Wen-Kai Lua, Tzu-Yu Chiub, Shu-Hsien Hunga,b, Ing-Lung Shihc, Yaw-Nan Changa,b* a Department of Food Engineering

b Department of Bioindustry Technology

c Department of Environmental Engineering, Da-Yeh University,Changhua, 515, Taiwan, R.O.C.

Download Citation:

|

Download PDF

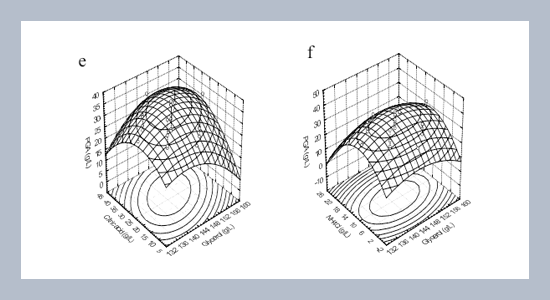

Response surface methodology (RSM) was employed to study the effects of four medium components (L-glutamic acid, citric acid, glycerol and NH4Cl) on the production of poly-γ-glutamic acid (PGA) in flask cultures by Bacillus licheniformis CCRC 12826 (ATCC 9945) with initial medium pH 6.5. The optimal PGA yield (35.34 g/L, average of four repeats) was appeared at the region where the respective concentrations (in g/L) of glutamic acid, citric acid, glycerol and NH4Cl were around 34.0, 26.0, 146.0 and 11.0, respectively. The optimized composition derived from RSM regression was (in g/L) glutamic acid 34.70, citric acid 27.00, glycerol, 145.45 and NH4Cl 10.49. With this composition, the PGA production was 33.20 g/L (average of eight repeats) after 96 h of cultivation, while the predicted maximum production was 35.52 g/L. The optimized medium resulted in significant increase of the PGA yield by B. licheniformis CCRC 12826 in shake-flask cultivation without any feeding process. In comparison with glutamic acid, citric acid and glycerol, NH4Cl represents a crucial role in PGA biosynthesis.ABSTRACT

Keywords:

Bacillus licheniformis; response surface methodology; poly-γ-glutamic acid

Share this article with your colleagues

[1] Shih, L. and Van, Y. T. 2001. The production of poly(γ-glutamic acid) from the microorganisms and its various applications. Bioresource Technology, 79: 207-225.REFERENCES

[2] Thorne, C. B., Gomez, C. G., Noyes, H. E., and Housewright, R. D. 1954. Production of glutamyl polypeptide by Bacillus subtilis. Journal of Bacteriology, 68: 307-315.

[3] Troy, F. A. 1973. Chemistry and biosynthesis of the poly(γ-glutamyl) capsule in Bacillus subtilis. 1. Properties of the membrane-mediated biosynthetic reaction. The Journal Biological Chemistry, 248: 305-316.

[4] Cheng, C., Asada, Y., and Aaida, T. 1989. Production of γ-polyglutamic acid by Bacillus subtilis A35 under denitrifying conditions. Agricultural and Biological Chemistry, 53: 2369-2375.

[5] Kubota, H., Matsunobu, T., Uotani, K., Takebe, H., Satoh, A., Tanaka, T., and Taniguchi, M. 1993. Production of poly(γ-glutamic acid) by Bacillus subtilis F-2-01. Bioscience, Biotechnology, and Biochemistry, 57: 1212-1213.

[6] Kunioka, M. and Furusawa, K. 1997. Poly(γ-glutamic acid) hydrogel prepared from microbial poly(γ-glutamic acid) and alkane diamine with water-soluble carbodiimide. Journal of Applied Polymer Science, 65: 1889-1893.

[7] Birrer, G. A., Cromwick A. M., and Gross, R. A. 1994. γ-Poly(glutamic acid) formation by Bacillus licheniformis: physiological and biochemical studies. International Journal of Biological Macromolecules, 16: 265-275.

[8] Cromwick, A. M., Birrer, G. A., and Gross, R. A. 1996. Effects of pH and aeration on γ-Poly(glutamic acid) formation by Bacillus licheniformis in controlled batch fermentor cultures. Biotechnology and Bioengineering, 50: 222-227.

[9] Shih, L., Van, Y. T., Yeh, L. C., Lin, H. G., and Chang, Y. N. 2001. Production of biopolymer flocculant from Bacillus licheniformis and its flocculation properties. Bioresource Technology, 78: 267-272.

[10] Shih, L., Van, Y. T., and Chang, Y. N. 2002. Application of statistical experimental methods to optimize production of poly(γ-glutamic acid) by Bacillus licheniformis CCRC 12826. Enzyme and Microbial Technology, 31: 213-220.

[11] Kunioka, M. and Goto, A. 1994. Biosynthesis of poly(γ-glutamic acid) from L-glutamine, citric acid and ammonium sulfate in Bacillus subtilis Applied Microbiology and Biotechnology, 40: 867-872.

[12] Kunioka, M. 1995. Biosynthesis of poly(γ-glutamic acid) from L-glutamine, citric acid and ammonium sulfate in Bacillus subtilis Applied Microbiology and Biotechnology, 44: 501-506.

[13] Zertuche, L. and Zall R. R. 1985. Optimizing alcohol production from whey using computer technology. Biotechnology and Bioengineering, 27: 547-554.

[14] Buchanan, R. L. and Philips, J. G. 1990. Response surface model for predicting the effects of temperature, pH, sodium chloride content, sodium nitrite concentration and atmosphere on the growth of Listeria monocutogenes. Journal of Food Protection, 53: 370-376.

[15] Prapulla, S. G., Jacob, S., Chand, N., Rajalakshmi, D., and Karanth, N. G. 1992. Maximization of lipid production by Rhodotroula gracilis CFR-1 using response surface methodology. Biotechnology and Bioengineering, 40: 965-969.

[16] Haltrich, D., Press, M., and Steiner, W. 1993. Optimization of a culture medium for increased xylanase production by a wild strain of Schizophyllum commune. Enzyme and Microbial Technology, 15: 854-860.

[17] Chang, Y. N., Huang, J. C., Lee, C. C., Shih, L., and Tzeng, Y. M. 2002. Use of response surface methodology to optimize culture medium for production of lovastatin by Monascus ruber. Enzyme and Microbial Technology, 30: 889-894.

[18] Lu, W. K. 2003. “Studies on Production of Poly(γ-glutamic acid) by Bacillus licheniformis CCRC 12826 with Response Surface Methodology”. Master Thesis of Department of Food Engineering, Da-Yeh University, Changhua, Taiwan, R.O.C. (in Chinese)

ARTICLE INFORMATION

Accepted:

2004-02-20

Available Online:

2004-03-02

Lu, W.-K., Chiu, T.-Y., Hung, S.H., Shih, I.-L., Chang, Y.-N., 2004. Use of response surface methodology to optimize culture medium for production of Poly-γ-glutamic acid by bacillus licheniformis, International Journal of Applied Science and Engineering, 2, 49–58. https://doi.org/10.6703/IJASE.2004.2.(1).49

Cite this article: