Mohamad Imron Mustajibab*, Udisubakti Ciptomulyonoa and Nani Kurniatia aDepartment of Industrial Engineering, Institut Teknologi Sepuluh Nopember. Surabaya, Jawa Timur 60111, Indonesia.

bDepartment of Industrial and Mechanical Engineering, Universitas Trunojoyo Madura. Bangkalan, Jawa Timur 69162, Indonesia.

Download Citation:

|

Download PDF

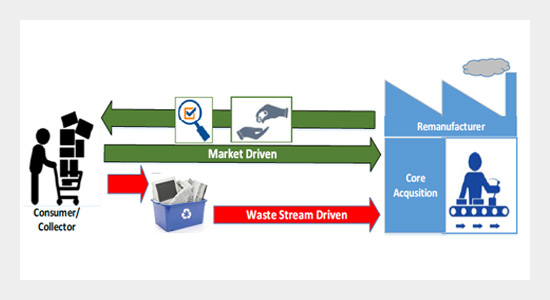

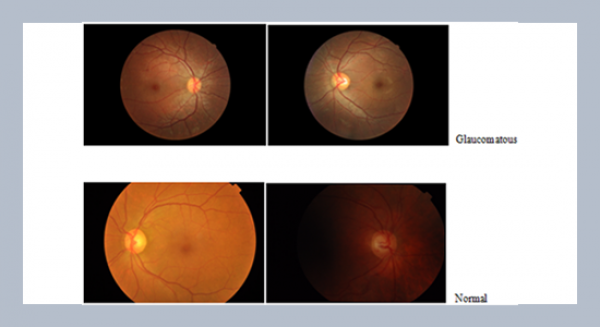

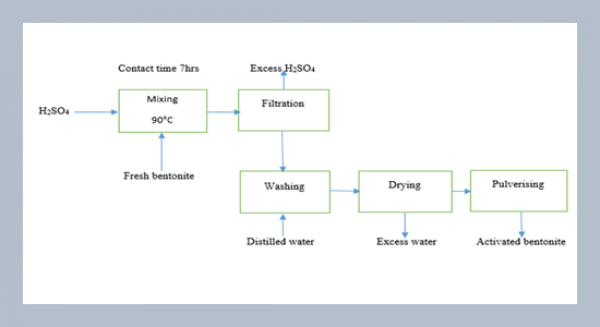

Remanufacturing is a major area of interest within the field of sustainable manufacturing. Since remanufacturing has widely recognized as a strategy to recover of used products. This recovery means that salvaged values in the used products can be generated again in multi-lifecycle of product through many operations in remanufacturing system. Previous research has established that there are many challenges in remanufacturing practices. The crucial challenge is a shortcoming of control respecting uncertainty in quality, quantity, and return time of a used product. The existence of quality uncertainty incurs risks to incoming core, to remanufacturing planning, and to remanufactured product itself. This uncertainty, if unmanaged correctly, could lead to high cost of quality and remanufacturing operations. Therefore, the main problem is how to analyze the causes of quality uncertainty in remanufacturing activities. In this work, the factors of quality uncertainty were investigated using a fish bone diagram as a tool for cause and effect analysis. This tool is particularly useful in investigating factors and root causes of the quality uncertainty problem in remanufacturing system. In the first step we show that the factors exist in core acquisition and remanufacturing activity. The next step, we propose a quality control framework for reducing quality uncertainty. The framework characteristic in this paper is generic in nature, so that it can be potential for general applicability in remanufacturing industries.ABSTRACT

Keywords:

Core acquisition; remanufacturing operations; core acceptance condition.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2019-05-29

Accepted:

2019-06-18

Available Online:

2019-06-01

Mustajib, M.I., Ciptomulyono, U., Kurniati, N. 2019. Determining factors of quality uncertainty and Its control analysis in remanufacturing system. International Journal of Applied Science and Engineering, 16, 35-45. https://doi.org/10.6703/IJASE.201906_16(1).035

Cite this article: