Ming-Gin Lee*, Yishuo Huang, and Yu-Cheng Kan Department of Construction Engineering, Chaoyang University of Technology, Wufong, Taichung County 41349, Taiwan, R.O.C.

Download Citation:

|

Download PDF

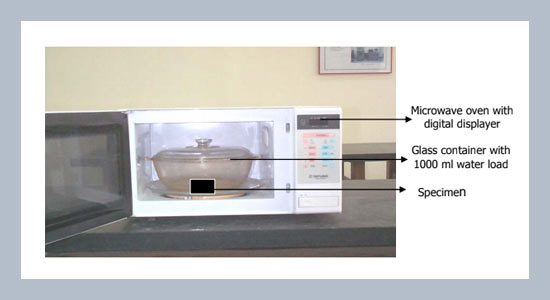

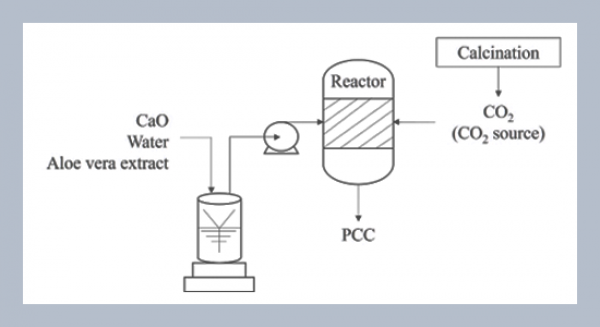

This study investigates the effects of steam and microwave curing on the strength developmentThis study investigates the effects of steam and microwave curing on the strength developmentand permeability of concrete. Two steam curing treatments, four microwave curingtimes and four types of concrete mix were used in this study. The test results indicated that microwaveheating could further increase the compressive strength of mortar and concrete. Pozzolanicreaction of silica fume, fly ash and blast-furnace slag was observed to be further promotedby steam-microwave curing. Mortar and concrete samples with 10% silica fume addedresponded well to microwave curing. The strength gain development of mortar and concrete appearedto level off after 40 minutes of microwave curing. Thus, a 40-minute microwave heatingtime appeared to be the optimal time for energy saving consideration. The microwave-curedconcrete did not show an increase in permeability relative to the concrete that was steam-cured,but showed an increase in strength. Thus, microwave heating may be a potentially attractivemethod for accelerating cement hydration.ABSTRACT

Keywords:

microwave heating; steam curing; compressive strength; rapid chloride permeability.

Share this article with your colleagues

[1] Young, C. H.1997. Effect of the MaterialProperties on High Performance ConcreteDue to Steam, Taiwan NationalScience Counsel, NSC 85- 2211- E- 011-007.REFERENCES

[2] Lee, M. G., and J. C. Chern, 1999. Effectof steam-curing cycle and Proportionmix on the strength of Precast Concrete,EASC-7: 1390-1395.

[3] Lee, M. G. 2000. Effect of steam-curingon the strength of Precast Concrete, Apaper Presented at the Seventh AnnualInternational Conference on CompositesEngineering (ICCE-7): 513-514.

[4] Lee, M. G. 2001. Effect of MicrowaveHeating and Steam Curing on theStrength of Cement Paste and Concrete,A paper Presented at the Eighth AnnualInternational Conference on CompositesEngineering (ICCE-8), Spain,Tenerife Island.

[5] Watson, A. 1968. Curing of concrete,Microwave Power Engineering, 2:108-118.

[6] Christopher K. Y. Leung and ThanakornPheeraphan 1995. Very high earlystrength of microwave cured concrete,Cement and Concrete Research, 25, 1:136-146.

[7] Wu, X., Dong, J. and Tang, M. 1987.Microwave curing technique in concretemanufactures, Cement Concrete Research,17, 2: 205-210.

[8] Hutchison, R. G., Chang, J. T., Jennings, H. M. and Brodwin, M. E. 1991. Thermalacceleration of Portland cementmortars with Microwave energy, Cementand Concrete Research, 21, 8: 795-799.

[9] Christopher, K. Y. Leung and Pheeraphan,T. 1995. Microwave curing of Portlandcement concrete: experimental resultsand feasibility for practical applications,Construction and Building Materials,9, 2: 67-73.

[10] Pheeraphan, T. and Christopher K. Y.Leung 1997. Freeze-thaw durability ofmicrowave cured air-entrained concrete,Cement and Concrete Research, 27, 4:427-435.

[11] Lee, M. G. 2007. A Preliminary Studyfor Strength and Durability of Microwaveand Steam Cured Concrete, paperaccepted for publication at the ASCEJournal of Materials in Civil Engineering.

[12] ASTM C1202-97, Standard Test Methodfor Electrical Indication of Concrete’sAbility to Resist Chloride Ion Penetration.

[13] Weng, T. L. and Yang, C. C. 2004. TheRelationship Between Chloride MigrationRate for Concrete and ChargePassed Rate in Accelerated Chloride MigrationTest, Journal of the Chinese Instituteof Engineers, 27, 5: 731-736.

ARTICLE INFORMATION

Accepted:

2007-07-13

Available Online:

2007-07-01

Lee, M.-G., Huang, Y., Kan, Y.-C. 2007. The strength and rapid chloride permeability of microwave cured concrete. International Journal of Applied Science and Engineering, 5, 53–63. https://doi.org/10.6703/IJASE.2007.5(1).53

Cite this article: