Dyi-Huey Changa,* and Jung-Chung Hungb aDepartment of Environmental Engineering and Management, Chaoyang University of Technology, Wufeng District, Taichung, Taiwan, R.O.C.

bDepartment of Mechanical Engineering, National Chin-Yi University of Technology, Taichung, Taiwan, R.O.C.

Download Citation:

|

Download PDF

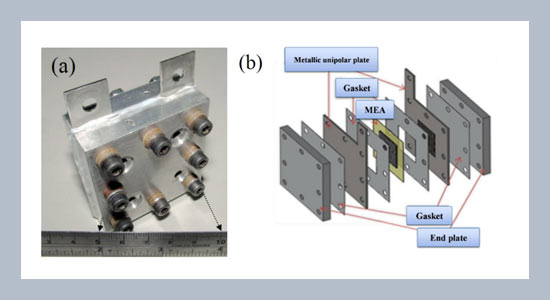

This study examines the effects of channel depths and anode flow rates on the performance of miniature proton exchange membrane fuel cells. The flow field is a three-pass serpentine structure, of which both the rib and channel widths are 500 μm and the channel depths are varied as 200, 400 and 600 m, in a reaction area of 4cm2. During the test, this study assemblies a cell with the carbon-paper membrane electrode assembly (MEA). The performance of the cell is evaluated based on three different channel depths with varying anode flow rates. The impact of MEA deformation is also examined. The results indicate that the impacts of MEA deformation might not be significant for a cell with sufficient channel depth. For all tests, the cell with median channel depth (400μm) yields best results. The cell with shallower channel depth prefers high flow rate because a higher flow rate can provide sufficient pressure to force the reactant to pass through channels in small cross-sectional area. The cell with deeper channel depth prefers low flow rate. This is because deeper channel depth does not require higher pressure to force the reactant to pass through channels. Instead, too high flow rate excessively increases flow velocity, which upsets the water balance in MEA and decreases cell performance.ABSTRACT

Keywords:

Metallic bipolar plate; MEA; fuel cell; channel depth.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2012-06-03

Revised:

2012-08-29

Accepted:

2012-10-17

Available Online:

2012-12-01

Chang, D.-H., Hung, J.-C. 2012. Effects of channel depths and anode flow rates on the performance of miniature proton exchange membrane fuel cells. International Journal of Applied Science and Engineering, 10, 273–280. https://doi.org/10.6703/IJASE.2012.10(4).273

Cite this article: