Ying-Tzu Ke1, Yung-Chiang Lin1*, Chia-Chi Cheng1, Jien-Chen Chen2, Yu-Hung Pai2, Keng-Tsang Hsu1 1 Department of Civil and Construction Engineering, Chaoyang University of Technology, Taichung City 413310, Taiwan, R.O.C. 2 Industrial Technology Research Institute, Chutung, Hsinchu 31057, Taiwan, R.O.C.

Download Citation:

|

Download PDF

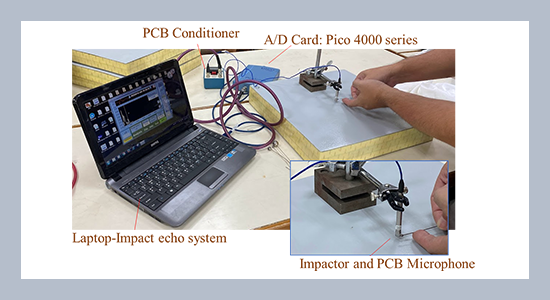

The sandwich composites in this study are laminated structures with two outer thin glass fiber reinforced panels and one or more thick lightweight foam panels as the core material. Such sandwich composites are often used in wind turbine blade. The Impact-Echo method using a microphone as a receiver was used to test the sandwich composite panel specimens. The signals were analysed in the frequency domain and normalized by the Rayleigh wave amplitude. Preliminary results show that thicker plates generally have a lower maximum peak frequency (MPF) for specimens without defects, but MPFs are more unstable due to the higher number of layers of the inner foam plate. Internal defects generated by excavating the core material, with lateral dimensions as small as 20 mm, can be identified from lower MPF and higher maximum peak amplitude in the normalized amplitude spectrum.ABSTRACT

Keywords:

Impact-Echo, Sandwich composites, Normalized amplitude spectrum, Wind turbine blades, Defect.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2022-11-22

Revised:

2023-01-03

Accepted:

2023-01-16

Available Online:

2023-02-22

Ke, Y.-T., Lin, Y.-C., Cheng, C.-C., Chen, J.-C., Pai, Y.-H., Hsu, K.-T. Preliminary study on defect detection for sandwich composites using Impact-Echo method. International Journal of Applied Science and Engineering, 20, 2022312. https://doi.org/10.6703/IJASE.202306_20(2).002

Cite this article:

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.