Samara Heliw Basheet, Roaa Hamed Latief * Department of Civil Engineering, College of Engineering, University of Baghdad, Baghdad, 10071, Iraq

Download Citation:

|

Download PDF

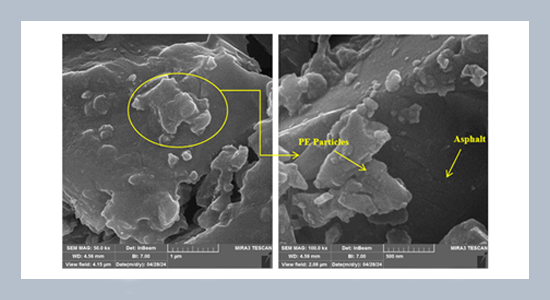

The performance of asphalt pavements is crucial due to heavy traffic loads from civil and industrial developments. Various additives and modifiers are used in flexible roads to improve their resistance to deterioration caused by climatic changes. From this context, modifying the asphalt binder with polymers is popular in asphalt pavement construction. The present research investigates the effect of Polyethylene (PE) polymers in powder form on the characteristics of asphalt mixtures since these polymers are composed of hydrocarbons. It is similar to asphalt binders, making them very effective in enhancing the performance of neat asphalt produced from the oil refinery. To confirm this, two types of PE, High-Density PE (HDPE) and Low-Density PE (LDPE), were blended with neat asphalt binder at different dosages of 0%, 2%, 4%, and 6% by the weight of asphalt binder. The physical tests, including penetration, ductility, softening point, and weight loss on heat, were conducted to examine neat and PE-modified binders' rheological properties, durability, and temperature sensitivity. Marshall stability, stiffness index, tensile strength, and Scanning Electron Microscope (SEM) were also employed to assess the performance of PE-modified asphalt mixtures. The findings reveal that incorporating PE into asphalt mixtures significantly improves their mechanical properties, and the most optimal results are achieved when using 6% of both HDPE and LDPE. Specifically, modifying the asphalt binder with the inclusion of 6% HDPE and LDPE presents a remarkable increase in stability of 167.6% and 150.9%, respectively, compared to conventional mixtures. The stiffness index is improved for HDPE and LDPE-modified mixtures, which offers these mixtures superior resistance to permanent deformation. The moisture damage resistance can be enhanced by modification of the asphalt binder with HDPE and LDPE, especially at the inclusion of 6%. SEM images of asphalt pavement demonstrate HDPE's superiority in terms of distribution and dispersion in asphalt binder. In conclusion, the properties of HDPE-modified mixtures are better than those of LDPE-modified and untreated mixtures.ABSTRACT

Keywords:

Marshall properties, Moisture damage, Polyethylene polymer, SEM, Wet mixing.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2024-07-27

Revised:

2024-11-25

Accepted:

2024-12-12

Available Online:

2025-01-03

Basheet S.H., Latief R.H. 2024. Assessment of the properties of asphalt mixtures modified with LDPE and HDPE polymers. International Journal of Applied Science and Engineering, 21, 2024265. https://doi.org/10.6703/IJASE.202412_21(5).007

Cite this article:

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.