Kesavamoorthi. R, Mohan Ganesh. G School of Civil Engineering, Vellore Institute of technology, Vellore, India

Download Citation:

|

Download PDF

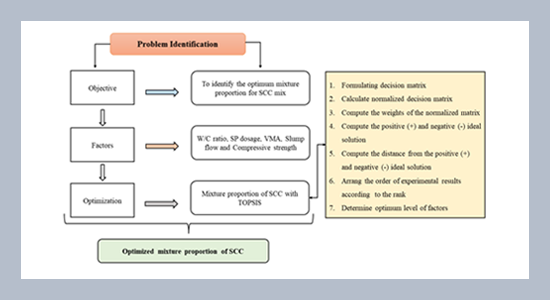

The process of concrete mix design encompasses numerous parameters. Finding the ideal mix design may be quite challenging for self-compacting concrete (SCC). This research aims to identify the best optimum mix proportions for SCC using TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) method. In this methodology, SCC mixtures with an extensive set of experimental data and performance measures are combined into a single value for optimizing. For this the required data sets of twenty-one SCC mixtures were developed utilizing the Nan-Su method with M50 grade of concrete and cast for finding fresh and mechanical properties. The slump flow was measured using EFNARC standards and compressive strength was measured. The input parameters for the TOPSIS method were slump flow, compressive strength, superplasticizer (SP), viscosity modifying agent (VMA), and the W/C ratio which were among the five criteria used to choose as alternatives among the twenty-one different mix proportions. Therefore, the experimental data set of SCC provides the essential data for the decision matrix. TOPSIS is a ranking algorithm for condensing the results of many different criteria into a single value. By evaluating and rating the various mixture proportions, the optimal one was identified which reduces the number of trail mixtures in future, as seen in the details given in this study. Further, the study will evaluate the effect of supplementary cementitious materials (SCMs) on the properties of SCC. The replacement of SCMs improves the fresh and mechanical properties compared to the control mix and SCMs promotes the sustainable and environmentally friendly construction practices.ABSTRACT

Keywords:

EFNARC, Nan-Su method, Self-compacting concrete, TOPSIS.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2024-08-31

Revised:

2025-03-01

Accepted:

2025-03-28

Available Online:

2025-04-25

Kesavamoorthi. R, Mohan Ganesh. G. 2025. Optimization of mixture proportions for self-compacting concrete using TOPSIS method. International Journal of Applied Science and Engineering, 22, 2024319.https://doi.org/10.6703/IJASE.202503_22(1).004

Cite this article:

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.