S. R. Raoa* and G. Padmanabhanb aDepartment of Mechanical Engineering, Sri Venkateswara College of Engineering & Technology, RVS Nagar, Chittoor, Andhra Pradesh, India

bDepartment of Mechanical Engineering, Sri Venkateswara College of Engineering, S.V.University, Tirupathi, Andhra Pradesh, India

Download Citation:

|

Download PDF

Aluminium metal matrix composites (AMMCs) are now gaining their usage in aerospace and automotive industries because of their inherent properties like high strength to weight ratio, low wear rate etc. Electrochemical Machining (ECM) allowed success in the production of newer materials, especially for the aerospace and biomedical applications. In this paper an attempt is made to machine the LM6 Al/B4Cp composites using electrochemical machining process. Boron carbide particles of 30 micron size are reinforced in LM6 Al alloy matrix with 2.5%, 5% and 7.5% by weight. Taguchi’s L27 orthogonal array is chosen to design the experiments and 27 tests are conducted to study the effect of various machining parameters like applied voltage, feed rate, electrolyte concentration and percentage of reinforcement on the material removal rate (MRR), surface roughness (SR) and radial over cut (ROC). Signal-to-noise (S/N), the analysis of variance (ANOVA) and regression analyses are employed to find the optimal levels and to analyze the effect of electrochemical machining parameters on MRR, SR and ROC. Confirmation tests with optimal levels of machining parameters are conducted to validate the test results. Experimental results have shown that the responses in ECM can be improved effectively through this approach. ABSTRACT

Keywords:

Electrochemical machining; taguchi method; Al/B4C composites; ANOVA.

Share this article with your colleagues

[1] Fortana, M. G. 1986. “Corrosion Engineering”. McGraw-Hill, New York.REFERENCES

[2] Senthilkumar, C., Ganesan, G., and Karthikeyan R. 2009. Study of electrochemical machining characteristics of Al/SiCp composites. International Journal of Advanced Manufacturing Technology, 43: 256-263.

[3] Kao, P. S. and Hocheng, H. 2003. Optimization of electrochemical polishing of stainless steel by grey relational analysis. Journal of Materials Processing Technology, 140: 255-259.

[4] Jagannath, M. and Bhattacharya, B. 2008. Investigation in to electrochemical micromachining (EMM) through response surface methodology based approach. International Journal of Advanced Manufacturing Technology, 35, 7: 821-832.

[5] Asoken, P., Ravi Kumar, R., Jeypaul, R., and Santhi, M. 2008. Development of multi-objective optimization models for electrochemical machining process. International Journal of Advanced Manufacturing Technology, 39: 55-63.

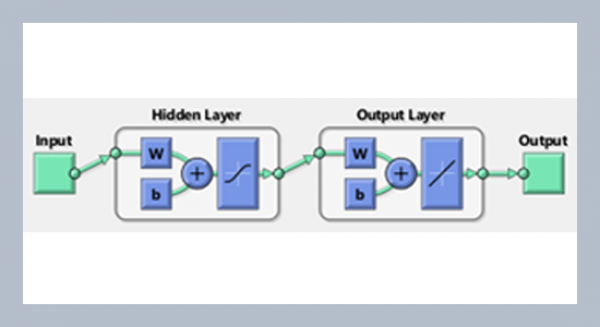

[6] Rama Rao, S., Sravan, C. R. M., Padmanabhan, G., and Pandu R. V. 2009. Fuzzy logic based forward modeling of electrochemical machining process. IEEE Proceedings of the World Congress on Nature and Biologically Inspired Computing, Chennai, India, pp.1431-1435.

[7] Rama Rao, S., Padmanabhan, G., Sureka, B., and Pandu R. V. 2009. Optimization of electrochemical machining process using evolutionary algorithms. Journal of machining and forming technology, 1(3/4): 265-278.

[8] Chakradhar, D. and Venu Gopal, A. 2011. Multi-objective optimization of electrochemical machining of EN31 steels by grey relational analysis. International Journal of Modeling and Optimization, 1, 2: 113-117.

[9] Sorkhel, S. K. and Bhattacharya, B. 1992. Parametric combinations for controlled machined rate and surface quality in electrochemical machining. In proceedings of the 15th All India machine tool design and research conference, 421-426.

[10] Yang, H. and Tarng, Y. S. 1998. Design optimization of cutting parameters for turning operations based on the Taguchi method. Journal of Materials Processing Technology, 84: 122-129.

[11] Palanikumar, 2008. Application of Taguchi and response surface methodologies for surface roughness in machining glass fiber reinforced plastics by PCD tooling. International Journal of Advanced Manufacturing Technology, 36: 19-27.

[12] Davidson, M. J., Balasubramanian, K., and Tagore, R. N. 2008. Surface roughness prediction of flow-formed AA6061 alloy by design of experiments. Journal of Materials Processing Technology, 202: 41-46.

ARTICLE INFORMATION

Received:

2013-08-05

Revised:

2013-12-02

Accepted:

2014-01-22

Available Online:

2014-06-01

Rao, S.R., Padmanabhan, G. 2014. Optimization of machining parameters in ECM of Al/B4C composites using taguchi method. International Journal of Applied Science and Engineering, 12, 87–97. https://doi.org/10.6703/IJASE.2014.12(2).87

Cite this article: