Oladeji Akanni Ogunwole* Mechanical Engineering Department, Federal University of Technology, Minna, Nigeria

Download Citation:

|

Download PDF

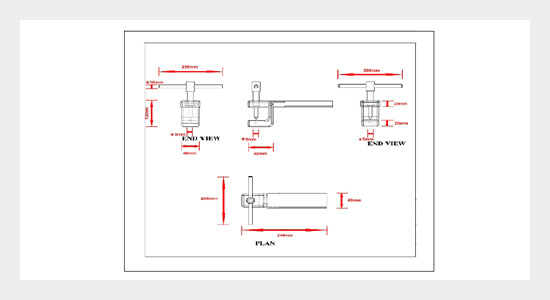

A manual rivet extractor was designed and fabricated to facilitate removal of blind rivets of sizes 4.0mm x 19mm and 4.8mm x 19mm from joints, machines and other structured assemblies without causing damages to joined components. The extractor parts were made up of mild steel. It had two head screw of 5mm and 4mm beak. It is a manually operated device that was readily be fabricated in simple workshop. Safety load of each head screw of 5mm and 4mm beak were calculated to be 120.69KN and 94.54KN respectively. The torques on them were 452.58Nm and 283.62Nm respectively. It is a robust and handy device that when operated carefully is expected to be useful for operator for a while.ABSTRACT

Keywords:

Extractor; rivet; beak; joint; torque

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Received:

2014-01-06

Revised:

2014-09-05

Accepted:

2015-02-05

Available Online:

2015-06-01

Ogunwole, O.A. 2015. Development of a rivet extractor. International Journal of Applied Science and Engineering, 13, 123–131. https://doi.org/10.6703/IJASE.2015.13(2).123

Cite this article: