Hadiseh Babazadeh1* and Sobhan Javan1 1Faculty of Electrical Engineering, Urmia University of Technology, Urmia 57166-17165, Iran

Download Citation:

|

Download PDF

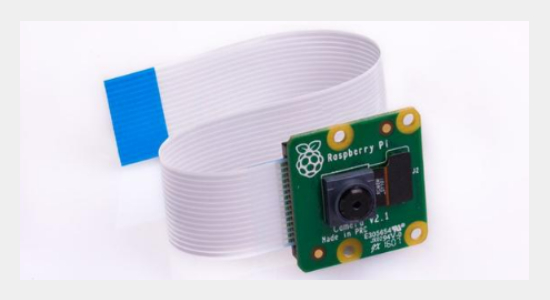

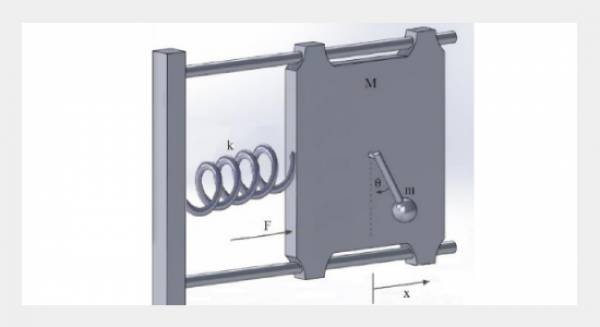

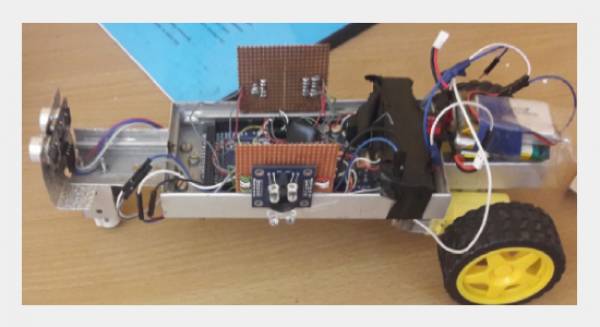

Object tracking is one of the main issues in image processing. A real-time CNC is designed and implemented in which the target image is taken using the digital camera every ten milliseconds. After extracting the new position, the target's exact location is sent to the CNC; then, the CNC pen will move to that location and copy the target path. In this project, a Raspberry Pi 3 Model B+ board is used as the processor and the controlling board, a Raspberry Pi digital camera is the input unit, and the CNC motors and its pen are the output unit. The target is a small dark dot moving on a white surface with the dimensions of 4.5 cm × 4.5 cm. The camera is placed under the surface, so a tiny magnet is used on the surface, which the user can easily displace to move the target. Kinematic analysis of the proposed structure is done using Denavit-Hartenberg parameters. The CNC is programmed in Python and implemented using stepper motors and an output plane. Template Matching TM_CCOEFF_NORMED function of the OpenCV image processing library of Python is used to read and detect the target. Various test results show that the machine is successful both in repeating the patterns created by the user and reproducing the same line without deviation.ABSTRACT

Keywords:

image processing, Python, Raspberry Pi, CNC, kinematics, Denavit-Hartenberg, stepper motor, digital camera

Share this article with your colleagues

[1] T. Yu, T. Liu, W. Wang, S. Yang, "Application of Image Processing Technology in INC," IEEE 6th World Congress on Intelligent Control and Automation, Vol. 2, pp. 6203-6207, 2006. [2] R. G. Lins, B. Guerreiro, P. R. M. De Araujo, R. Schmitt, "In-process tool wear measurement system based on image analysis for CNC drilling machines," IEEE Transactions on Instrumentation and Measurement, 69(8), 5579-5588, 2019. https://doi.org/10.1109/TIM.2019.2961572 [3] V. Itthisupornrat, S. Kiatsunthorn, "Duplicate a blank key using image processing," IEEE SICE-ICASE International Joint Conference, pp. 5711-5714, Oct. 2006. https://doi.org/10.1109/SICE.2006.314640 [4] A. Siddhpura, R. Paurobally, "A review of flank wear prediction methods for tool condition monitoring in a turning process," International Journal of Advanced Manufacturing Technology, 65(1-4), 371-393, 2013. https://doi.org/10.1007/s00170-012-4177-1 [5] L. Gomes, S. Bogosyan, "Current trends in remote laboratories," IEEE Transactions on industrial electronics, 56(12), pp. 4744-4756, 2009. https://doi.org/10.1109/TIE.2009.2033293 [6] F. Bakhshande, H. D. Taghirad, "Visual Tracking using Kernel Projected Measurement and Log-Polar Transformation," International Journal of Robotics, Vol. 4, No. 1, pp. 1-11, 2015. [7] K. Horak, L. Zalud, "Image processing on raspberry pi for mobile robotics," International Journal of Signal Processing Systems, 4(2), 1-5, 2016. [8] W. Chantara, J. H. Mun, D. W. Shin, Y. S. Ho, "Object tracking using adaptive template matching," IEIE Transactions on Smart Processing and Computing, 4(1), 1-9, 2015. https://doi.org/10.5573/IEIESPC.2015.4.1.001 [9] M. Sharikmaslat, R. Sidhaye, A. Narkar, "Image Processing Based Human Pursuing Robot," IEEE 3rd International conference on Electronics, Communication and Aerospace Technology (ICECA) pp. 702-704, Jun. 2019. https://doi.org/10.1109/ICECA.2019.8821861 [10] S. Tully, H. Choset, "A filtering approach for image-guided surgery with a highly articulated surgical snake robot," IEEE Transactions on Biomedical Engineering, 63(2), 392-402, 2015. https://doi.org/10.1109/TBME.2015.2461531 [11] R. Szabo, A. Gontean, "Industrial robotic automation with Raspberry PI using image processing," IEEE International Conference on Applied Electronics (AE), pp. 265-268, Sep. 2016. https://doi.org/10.1109/AE.2016.7577287 [12] S. Shirmohammadi, A. Ferrero, "Camera as the instrument: The rising trend of vision-based measurement," IEEE Instrumentation & Measurement Magazine, 17(3), pp. 41-47, 2014. https://doi.org/10.1109/MIM.2014.6825388 [13] S. H. Ahmed, N. Razzaq, Z. Malik, U. Qadeer, I. Sarfraz, A. Sharif, "Design & fabrication of MATLAB based solar powered CNC machine," IEEE 3rd International Conference on Control Science and Systems Engineering (ICCSSE), pp. 265-268, Aug. 2017. https://doi.org/10.1109/CCSSE.2017.8087937 [14] C. R. Severance, S. Blumenberg, Python for Everybody, Create Space Independent, 2016. [15] P. Corke, Robotics Vision and Control, Springer, 2017. https://doi.org/10.1007/978-3-319-54413-7 [16] Y. Chou, W. Liao, M. Chang, P. Lin, "An Intelligent Image Processing System for Real-Time Detection of Surface Flaws," International Journal of Automation and Smart Technology, Vol. 6, No.2, 2016. https://doi.org/10.5875/ausmt.v6i1.1006 [17] J. Tang, C. Tsai, F. Tai, "Object Recognition and Cooperative Pick-and-Place of a Single Spherical Wheeled Mobile Robot with Dual Arms," International Journal of Automation and Smart Technology, Vol. 8, No.1, 2018. https://doi.org/10.5875/ausmt.v8i1.1574 [18] Gareth Halfacree, The Official Raspberry Pi Beginner's Guide, 3rd edition, Raspberry Pi Press, 2019REFERENCES

ARTICLE INFORMATION

Received:

2021-12-14

Revised:

2022-05-16

Accepted:

2022-06-24

Available Online:

2022-06-01

Babazadeh. H. and Javan. S. (2022) Real Time Image Processing on Object Tracking CNC. Int. j. autom. smart technol. https://doi.org/10.5875/ausmt.v12i1.2386

Cite this article:

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.