Trung-Kien Vi1,4*, Yung-Chou Kao2, Sheng-Jhe Chen2, Guo-Hua Feng3, and Sung-Yan Tsai1 1Department of Mechanical Engineering, National Chung Cheng University, No. 168, Sec. 1, University Rd., Minhsiung Township, Chiayi County 621301, Taiwan (R.O.C.)

2Advanced Institute of Manufacturing with high-tech Innovations, National Chung Cheng University, No. 168, Sec. 1, University Rd., Minhsiung Township, Chiayi County 621301, Taiwan (R.O.C.)

3Department of Power Mechanical Engineering, National Tsing Hua University, No. 101, Section 2, Kuang-Fu Road, Hsinchu City 30013, Taiwan (R.O.C.)

4Faculty of Electromechanic and Electronics, Lac Hong University, No. 10, Huynh Van Nghe Street, Buu Long ward, Bien Hoa City, Dong Nai Province, Viet Nam.

Download Citation:

|

Download PDF

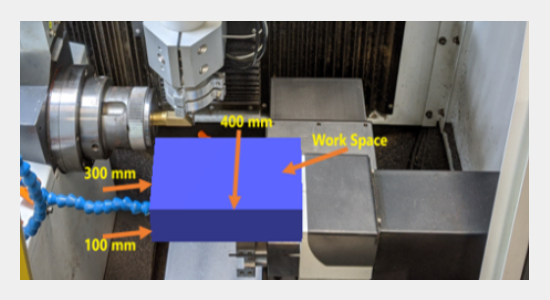

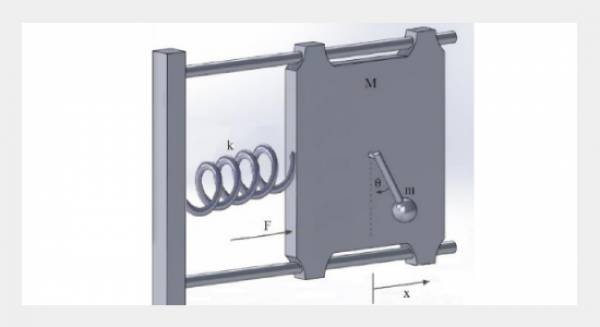

In theoretically traditional practice, the cutting force calculation/prediction based on the cutting force coefficients (CFCs) will not be affected by the properties of the machine tool such as the structural dynamics and the Frequency Response Function (FRF), etc. It means the CFCs are related only to the paired cutting tool and workpiece, but not the machine. However, it seems to be not the same in practice. This paper proposes an alternative method by conducting the cutting test experiment on the other machines that have enough working space for a dynamometer to be installed for the cutting test, and then applying it to a small working space machine. A series of experiments had been designed for cutting test and tapping test to verify the proposed method. This paper then focused on the exploration of varieties that influence the cutting forces. Finally, a new stable machining method has been successfully developed and verified with a case study by using a real seven-axis mill-turn machine tool (MTM) different from the machine tools used for the cutting test.ABSTRACT

Keywords:

Stability Lobe Diagram; Small-workspace Mill-Turn; Stable Machining; Cutting Force Coefficients

Share this article with your colleagues

[1] Lee, P and Altintas, Y, "Prediction of ball-end milling force from orthogonal cutting data". Int, J. Mach. Tools Manufact, Vol. 36, No. 9, pp. 1059-1072, 1996. https://doi.org/10.1016/0890-6955(95)00081-X [2] Shirase, K and Altintas, Y, "Cutting Force and dimensional surface error generation in peripheral milling with variable pitch helical end mills", Int, J. Mach. Tools Manufact, Vol. 36, No. 5, pp. 567-584, 1996. https://doi.org/10.1016/0890-6955(95)00063-1 [3] Budak, E. Altintas, Y. and E. J. A. Armarego, "Prediction of Milling Force Coefficients from Orthogonal Cutting Data", Journal of Manufacturing Science and Engineering 118(2): 216-224, 1996. https://doi.org/10.1115/1.2831014 [4] Altintaş, Y. and Lee, P, "A General Mechanics and Dynamics Model for Helical End Mills", CIRP Annals 45(1): 59-64, 1996. https://doi.org/10.1016/S0007-8506(07)63017-0 [5] Smith, S., and Tlusty, J, "Update on High-Speed Milling Dynamics". Journal of Manufacturing Science and Engineering, 112: 142-149, 1990. https://doi.org/10.1115/1.2899557 [6] Smith, S. and Tlusty, J, "An Overview of Modeling and Simulation of the Milling Process", Journal of Manufacturing Science and Engineering, 113: 169-175, 1991. https://doi.org/10.1115/1.2899674 [7] Altintas, Y., Budak, E, "Analytical Prediction of Stability Lobes in Milling", CIRP Annals, Vol. 44, pp. 357-362, 1995. https://doi.org/10.1016/S0007-8506(07)62342-7 [8] Budak, E. and Altintas, Y, "Analytical Prediction of Chatter Stability in Milling-Part II: Application of the General Formulation to Common Milling Systems." Journal of Dynamic Systems, Measurement, and Control 120(1): 31-36, 1998. https://doi.org/10.1115/1.2801318 [9] Turner, S., Merdol, D., Altintas, Y., and Ridgway K, "Modelling of the stability of variable helix end mills", International Journal of Machine Tools and Manufacture 47(9): 1410-1416, 2007. https://doi.org/10.1016/j.ijmachtools.2006.08.028 [10] Shamoto, E., and Akazawa, K, "Analytical prediction of chatter stability in ball-end milling with tool inclination", CIRP Annals 58(1): 351-354, 2009. https://doi.org/10.1016/j.cirp.2009.03.087 [11] Wan, M., Wang Ting, Y., Hong Zhang, W., and Dang Wei, J, "Prediction of chatter stability for multiple-delay milling system under different cutting force models", International Journal of Machine Tools and Manufacture 51(4): 281-295, 2011. https://doi.org/10.1016/j.ijmachtools.2010.12.007 [12] Kao, Y- C., Nguyen, Nhu-Tung, Chen, Mau-Sheng, and Huang, Shyh-Chour, "A combination method of the theory and experiment in determination of cutting force coefficients in ball-end mill processes", Journal of Computational Design and Engineering 2(4): 233-247, 2015. https://doi.org/10.1016/j.jcde.2015.06.005 [13] Sun, Y., and Jiang S., "Predictive modeling of chatter stability considering force-induced deformation effect in milling thin-walled parts", International Journal of Machine Tools and Manufacture 135: 38-52, 2018. https://doi.org/10.1016/j.ijmachtools.2018.08.003 [14] Altintas, Y., Stepan, G., Merdol, D., Dombovari, Z, "Chatter stability of milling in frequency and discrete time domain", CIRP Journal of Manufacturing Science and Technology 1(1): 35-44, 2008. https://doi.org/10.1016/j.cirpj.2008.06.003 [15] Insperger, T. and Stépán, G, "Semi-discretization method for delayed systems", International Journal for Numerical Methods in Engineering 55(5): 503-518, 2002. https://doi.org/10.1002/nme.505 [16] Insperger, T. and Stépán, G, "Updated semi-discretization method for periodic delay-differential equations with discrete delay", International Journal for Numerical Methods in Engineering 61(1): 117-141, 2004. https://doi.org/10.1002/nme.1061 [17] Ding, Y., Zhu Min, L., Jian Zhang, X., and Ding, H, "A full-discretization method for prediction of milling stability", International Journal of Machine Tools and Manufacture 50(5): 502-509, 2010. https://doi.org/10.1016/j.ijmachtools.2010.01.003 [18] Sun, T., Fang Qin, L., Can Fu, Y., and Ming Hou, J, "Chatter stability of orthogonal turn-milling analyzed by complete discretization method", Precision Engineering 56: 87-95, 2019. https://doi.org/10.1016/j.precisioneng.2018.10.012 [19] Kara, M. E., and Budak, E, "Optimization of Turn-milling Processes", Procedia CIRP 33(2015): 476-483, 2015. https://doi.org/10.1016/j.procir.2015.06.057 [20] Yan, R., Tang, X.W., Peng, F.Y., Wang, Y and Qiu, F, "The effect of variable cutting depth and thickness on milling stability for orthogonal turn-milling", The International Journal of Advanced Manufacturing Technology 82(1-4): 765-777, 2016. https://doi.org/10.1007/s00170-015-7418-2 [21] Zhan, D., Jiang, S., Niu, J., and Sun, Y, "Dynamics modeling and stability analysis of five-axis ball-end milling system with variable pitch tools", International Journal of Mechanical Sciences 182: 105774, 2020. https://doi.org/10.1016/j.ijmecsci.2020.105774 [22] Tang, X., Peng, F., Yan, R., Zhu, Z., Li. Z and Xin, S, "Nonlinear process damping identification using finite amplitude stability and the influence analysis on five-axis milling stability", International Journal of Mechanical Sciences 190: 106008, 2021. https://doi.org/10.1016/j.ijmecsci.2020.106008 [23] Wang, Minghai, Gao, Lei, Zheng, Yaohui, "An examination of the fundamental mechanics of cutting force coefficients", International Journal of Machine Tools & Manufacture 78 (2014) 1-7. https://doi.org/10.1016/j.ijmachtools.2013.10.008 [24] Altintas, Y. and J. H. Ko, "Chatter Stability of Plunge Milling", CIRP Annals, Volume 55, Issue 1, 2006, Pages 361-364, 2006. https://doi.org/10.1016/S0007-8506(07)60435-1 [25] Özşahin, O., Budak, E., Özgu ̈ven, H.N, "Identification of bearing dynamics under operational conditions for chatter stability prediction in high speed machining operations", Precision Engineering, Volume 42, October 2015, Pages 53-65, 2015. https://doi.org/10.1016/j.precisioneng.2015.03.010 [26] Comak, A., and E. Budak, "Modeling dynamics and stability of variable pitch and helix milling tools for development of a design method to maximize chatter stability", Precision Engineering 47: 459-468, 2017. https://doi.org/10.1016/j.precisioneng.2016.09.021 [27]Mohammadi, Y., Milad,A., Budak, E, "Suppressing vibration modes of spindle-holder-tool assembly through FRF modification for enhanced chatter stability", CIRP Annals 67(1): 397-400, 2018. https://doi.org/10.1016/j.cirp.2018.03.003 [28] Tunc, L. T., Mohammadi, Y., Budak, E, "Destabilizing effect of low frequency modes on process damped stability of multi-mode milling systems", Mechanical Systems and Signal Processing 111: 423-441, 2018. https://doi.org/10.1016/j.ymssp.2018.03.051 [29] Postel, M., Aslan, D., Wegener, K., Altintas, Y, "Monitoring of vibrations and cutting forces with spindle mounted vibration sensors", CIRP Annals 68(1): 413-416, 2019. https://doi.org/10.1016/j.cirp.2019.03.019 [30] Budak, E., Comak, A., Ozturk, E, "Stability and high performance machining conditions in simultaneous milling", CIRP Annals 62(1): 403-406, 2013. https://doi.org/10.1016/j.cirp.2013.03.141 [31] Budak, E, "Analytical models for high performance milling. Part II: Process dynamics and stability", International Journal of Machine Tools and Manufacture, Volume 46, Issues 12-13, October 2006, Pages 1489-1499, 2006. https://doi.org/10.1016/j.ijmachtools.2005.09.010 [32] Özşahin, O., Özgu ̈ven, H.N., and Budak, E, "Analysis and compensation of mass loading effect of accelerometers on tool point FRF measurements for chatter stability predictions", International Journal of Machine Tools and Manufacture 50(6): 585-589, 2010. https://doi.org/10.1016/j.ijmachtools.2010.02.002 [33] Kurata, Y., Doruk Merdol, S., Altintas, Y., Suzuki, N., Shamoto, E, "Chatter Stability in Turning and Milling with in Process Identified Process Damping", Journal of Advanced Mechanical Design, Systems, and Manufacturing 4(6): 1107-1118, 2010. https://doi.org/10.1299/jamdsm.4.1107 [34] Yang, Y., Mun ̃oa. J., Altintas, Y, "Optimization of multiple tuned mass dampers to suppress machine tool chatter", International Journal of Machine Tools and Manufacture 50(9): 834-842, 2010. https://doi.org/10.1016/j.ijmachtools.2010.04.011 [35] Budak, E. and E. Ozturk, "Dynamics and stability of parallel turning operations". CIRP Annals, Volume 60, Issue 1, 2011, Pages 383-386, 2011. https://doi.org/10.1016/j.cirp.2011.03.028 [36] Ozturk, E., Comak, A., Budak, E, "Tuning of tool dynamics for increased stability of parallel (simultaneous) turning processes", Journal of Sound and Vibration 360: 17-30, 2016. https://doi.org/10.1016/j.jsv.2015.09.009 [37] Azvar, M., and E. Budak, "Multi-dimensional chatter stability for enhanced productivity in different parallel turning strategies", International Journal of Machine Tools and Manufacture 123: 116-128, 2017. https://doi.org/10.1016/j.ijmachtools.2017.08.005 [38] Quintana, G., Ciurana, J, "A new experimental methodology for identification of stability lobes diagram in milling operations", International Journal of Machine Tools and Manufacture 48(15): 1637-1645, 2008. https://doi.org/10.1016/j.ijmachtools.2008.07.006 [39] Paliwal, V., Babu, N.R, "Prediction of Stability Lobe Diagram in High-Speed Milling by Operational Modal Analysis", 48th SME North American Manufacturing Research Conference, NAMRC 48 (Cancelled due to COVID-19), 2020. https://doi.org/10.1016/j.promfg.2020.05.049 [40] Ozkirimli, O., Tunc, L. T., Budak, E, "Generalized model for dynamics and stability of multi-axis milling with complex tool geometries", Journal of Materials Processing Technology 238: 446-458, 2016. https://doi.org/10.1016/j.jmatprotec.2016.07.020 [41] Dai, Y., Li, H., Wei, Z.C., Zhang, H, "Chatter stability prediction for five-axis ball end milling with precise integration method", Journal of Manufacturing Processes 32: 20-31, 2018. https://doi.org/10.1016/j.jmapro.2018.01.008 [42] Hayasaka, T., Jung, H., Azuma, K., Shamoto, E, "Consolidated chatter stability prediction model considering material removing and ploughing processes", Precision Engineering 59: 120-133, 2019. https://doi.org/10.1016/j.precisioneng.2019.06.006 [43] Itoh, M., Hayasaka, T., Shamoto, E, "High-efficiency smooth-surface high-chatter-stability machining of thin plates with novel face-milling cutter geometry", Precision Engineering 64: 165-176, 2020. https://doi.org/10.1016/j.precisioneng.2020.03.024 [44] Itoh, M., Hayasaka, T., Shamoto, E, "Novel geometrical design of turning inserts for high-efficiency smooth-surface high-chatter-stability cutting", Precision Engineering 64: 138-146, 2020. https://doi.org/10.1016/j.precisioneng.2020.03.018 [45] Nam, S., Hayasaka, T., Jung, H., Shamoto, E, "Proposal of novel chatter stability indices of spindle speed variation based on its chatter growth characteristics", Precision Engineering 62: 121-133, 2020. https://doi.org/10.1016/j.precisioneng.2019.11.018 [46] Kao,Y- C., Chen, S.J., Vi, T.K., Feng, G.H and Tsai, S.Y, "Study of milling machining roughness prediction based on cutting force", in IOP Conference Series: Materials Science and Engineering, Volume 1009, The 5th International Conference on Computing and Solutions in Manufacturing Engineering (CoSME'20), Brasov, Romania, 7-10 October 2020.https://doi.org/10.1088/1757-899X/1009/1/012027 [47] Altintas, Y, Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design, 2nd ed., New York: Cambridge University Press; ISBN978-1-00148-0, Chapter 2, Page 47, 2012. [48] Tony L, Schmitz. K Scott, Smith. Kevin S, Smith, "Machining Dynamics - Frequency Response to Improved Productivity", ISBN 978-0-387-09644-5, Chapter 4, Page 150-159, 2009. [49] Product of the Tongtai Machine & Tool Co. Ltd., https://www.tongtai.com.tw/en/product-detail.php?id=26, Online accessed 20 May 2021. [50] Product of the Yeong Chin Machinery Industries Co. Ltd., Machine & Tool Co. Ltd., https://www.ycmcnc.com/, and https://www.techspex.com/machining-centers/ycm(2460)/5003, Online accessed 12 September 2021. [51] Product of the Precision Machinery Research & Development Center, https://www.pmc.org.tw/, Online accessed 20 May 2021[52] Benardos, P. G., & Vosniakos, G, "Predicting surface roughness in machining: a review", International Journal of Machine Tools and Manufacture, 6:43(8):833-844, 2003. https://doi.org/10.1016/S0890-6955(03)00059-2 [53] BS EN ISO 4287:1997, "Geometrical product specification (GPS). Surface texture. Profile method. Terms, definitions, and surface texture parameters", STANDARD by British Standard / European Standard / International Organization for Standardization. [54] Mitutoyo, "Portable Surface Roughness Tester - SURFTEST SJ-410 Series", https://www.mitutoyo.com/wp-content/uploads/2013/02/2110_SJ-410.pdf, Online accessed 20 May 2021. [55] Serope Kalpakjian, and Steven R. Schmid, "Manufacturing Engineering and Technology", Sixth Edition in SI Units, Prentice Hall, 2009, Chapter 23, Page 636.REFERENCES

ARTICLE INFORMATION

Received:

2022-03-15

Revised:

2022-05-08

Accepted:

2022-06-24

Available Online:

2022-06-01

Vi. T.K., Kao. Y. C., Chen. S. J., Feng. G. H., and Tsai. S. Y. (2022) An Alternative Method for Stable Machining on A Small Workspace Mill-Turn Machine. Int. j. autom. smart technol. https://doi.org/10.5875/ausmt.v12i1.2406

Cite this article:

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.