Levente L. Diosady* Department of Chemical Engineering and Applied Chemistry University of Toronto 200 College St., Toronto, Ontario, Canada M5S 3E5

Download Citation:

|

Download PDF

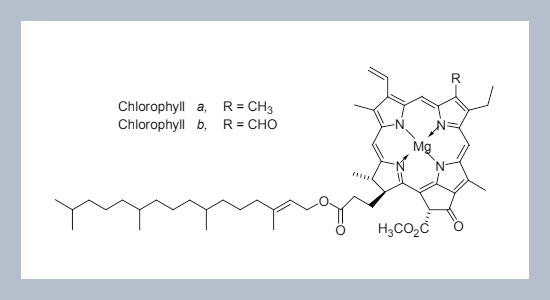

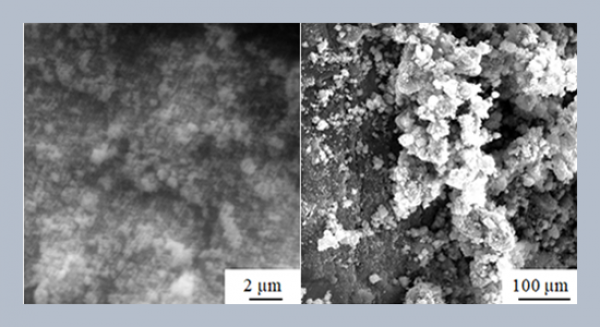

The chlorophyll content of canola oil, especially when extracted from frost-damaged seed is high, and results in dull, dark brown oil unless very large quantities of bleaching clay are used. We found that treatment with phosphoric acid, under vacuum in the absence of moisture precipitates most of the chlorophyll. At 140°C 2400 mg/L phosphoric acid precipitated 98 % of the chlorophyll in canola oil after 15 minutes of gentle stirring under vacuum of ~ 30 mmHg (4kPa). Chlorophyll levels were reduced from 23.8 mg/L to less than 0.5 mg/L. This was further reduced to > 0.05 mg/L with caustic refining and bleaching. A similar reduction in chlorophyll level was obtained with 5000 mg/L sulfuric acid at room temperature. Mass spectrometric analysis indicates that the chlorophyll is irreversibly converted to oil insoluble pheophorbides by the treatment. A mechanism is proposed. It was shown that the precipitated pigment may be left in the crude oil, as it will be removed during caustic refining. Thus the process requires only the addition in front of the caustic refining step of a heat exchanger and a vacuum mixing vessel with 15 min. residence time. The process was demonstrated on pilot and full scales. It has been patented and commercially implemented. ABSTRACT

Keywords:

Chlorophyll removal; edible oil processing; canola oil; pheophorbides.

Share this article with your colleagues

REFERENCES

ARTICLE INFORMATION

Accepted:

2005-09-23

Available Online:

2005-10-03

Diosady, L.-L. 2005. Chlorophyll removal from edible oils. International Journal of Applied Science and Engineering, 3, 81–88. https://doi.org/10.6703/IJASE.2005.3(2).81

Cite this article: