M. Chandra Sekhar Reddya and A. S. Sekharb* aResearch Scholar, Mechanical Engg. Dept., IIT Madras, Chennai, India

bProfessor, Mechanical Engineering Department, IIT Madras, Chennai, India

Download Citation:

|

Download PDF

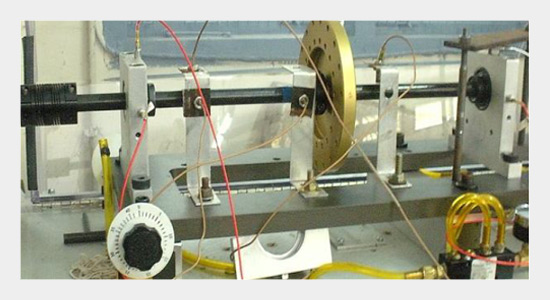

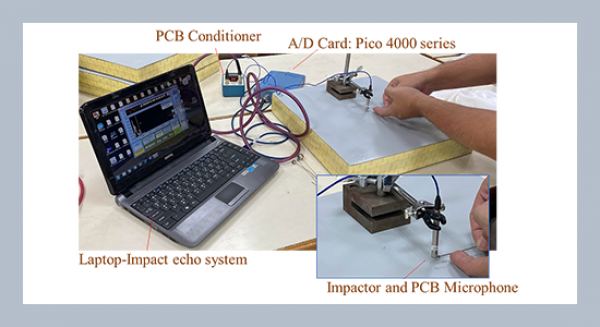

Rotating machinery is common in any industry. Rotating machinery in the modern era are designed for higher running speeds, tighter clearances and working under extreme conditions enhancing efficiency of the system to produce and transmit more power. All these lead to many rotordynamic challenges. Main cause of vibrations is faults in the rotating systems like unbalance, looseness, etc. In this paper a method is proposed to identify unbalance and looseness in rotor bearing system using artificial neural networks (ANN) by two different methods; one is by statistical features and the second by amplitude in frequency domain. In the first case statistical features are used to train and test the ANN, and in the second case amplitude in frequency domain is used to train and test the ANN. Experiments are conducted on the rotor bearing system running at 40 Hz and vibration data is collected by simulating different unbalance conditions in the rotor. And also experiments are conducted by creating looseness in the system by loosening the pedestal bolt. Various statistical features and amplitudes in frequency domain are extracted separately from this vibration data and are fed to neural network. It is observed that statistical features are giving good results over frequency domain amplitudes. ANNs are used to identify the unbalance severity and looseness. These results are useful for making maintenance decision.ABSTRACT

Keywords:

Unbalance; looseness; rotor; vibration analysis; neural networks

Share this article with your colleagues

[1] Braun, S. 1986. “Mechanical Signature Analysis: Theory and Application”. Academic Press, London.REFERENCES

[2] Lei, Y., He, Z., and Zi, Y. 2008. A new approach to intelligent fault diagnosis of rotating machinery, Expert Systems with Applications, 35, 1: 1593-1600.

[3] Vowk, V. 1991. “Machinery Vibration”. McGraw-Hill, New York.

[4] Genta, G. and Bona, F. D. 1989. Unbalance response of rotors: a modal approach with some extensions to damped natural systems, Journal of Sound and Vibration, 140, 1: 129-153.

[5] Goldman, P. and Muszynska, A. 1991. Analytical and experimental simulation of loose pedestal dynamic effects on a rotating machine vibrational response, Rotating Machinery and Vehicle Dynamics, ASME DE-Vol. 35, 1: 11-17.

[6] Chu, F. and Zhang, Z. 1998. Bifurcation and chaos in a rub-impact Jeffcott rotor system, Journal of Sound and Vibration, 210, 1: 1-18.

[7] Kim,Y. B. and Noah, S. T. 1991. Stability and bifurcation analysis of oscillators with piecewise-linear characteristic: a general approach, Transactions of the ASME Journal of Applied Mechanics, 58, 1: 545-553.

[8] Chu, F. and Holmes, R. 1998. Efficient computation on nonlinear responses of a rotating assembly incorporating the squeeze-film damper. Computer Methods in Applied Mechanics and Engineering, 164, 1: 363-373.

[9] Curti, G., Raffa, F. A., and Vatta, F. 1992. Unbalance response of rotor systems by dynamic stiffness method, Mechanics Research Communications, 19 (4), 1: 351-359.

[10] Sekhar, A. S. 2005. Identification of Unbalance and Crack Acting Simultaneously in a Rotor System: Modal Expansion versus Reduced Basis Dynamic Expansion, Journal of Vibration and Control, 11 (9), 1: 1125-1145.

[11] Zio, E. and Gola, G. 2009. A neuro-fuzzy technique for fault diagnosis and its application to rotating machinery. Reliability Engineering and System Safety, 94, 1: 78-88.

[12] Sanz, J., Perera, R., and Huerta, C. 2007. Fault diagnosis of rotating machinery based on auto-associative neural networks and wavelet transforms, Journal of Sound and Vibration, 302, 1: 981-999.

[13] Li, B., Mo-Yuen, and James, C. H. 2000. Neural network based motor rolling bearing fault diagnosis, IEEE Transaction on Industrial Electronics, 47 (5), 1: 1060-1069.

[14] Samanta, B. 2004. Gear fault diagnosis using artificial neural networks and support vector mechanics with genetic algorithms, Mechanical System and Signal Processing, 18 (3), 1: 625-649.

[15] Chen, D. and Wang, W. J. 2002. Classification of wavelet patterns using multilayer neural networks, Mechanical Systems and Signal Processing, 16 (4), 1: 695-704.

[16] Paya, B. A., East, I. I., and Badi, M. N. M. 1997. Artificial neural network based fault diagnostics of rotating machinery using wavelet transform as a preprocessor, Mechanical Systems and Signal Processing, 11 (5), 1: 751-765.

[17] Kankar, P. K., Satish C. S., and Harsha, S. P. 2011. Fault diagnosis of ball bearings using machine learning methods, Expert Systems with Applications, 38, 1: 1876-1886.

[18] Yiakopoulos, C. T., Gryllias, K. C., and Antoniadis, I. A. 2011. Rolling element bearing fault detection in industrial environments based on a K-means clustering approach, Expert Systems with Applications 38, 2888-2911.

[19] Taplak, H., Erkaya, S., and Uzmay, I. 2012. Experimental analysis on fault detection for a direct coupled rotor-bearing system, Measurement, http://dx.doi.org/10.1016/ j.measurement.

[20] Sinha., J. K. and Elbhbah, K. 2012. A future possibility of vibration based condition monitoring of rotating machines, Mechanical Systems and Signal Processing.http://dx.doi.org/10.1016/ j.ymssp.

[21] Wang, C. C., Kang, Y., Shen, P. C., Chang, Y. P., and Chung, Y. L. 2010. Applications of fault diagnosis in rotating machinery by using time series analysis with neural network, Expert Systems with Applications, 37, 1696-1702.

[22] Kalkat, M., Yildirim, S., and Uzmay, I. 2005. Design of artificial neural networks for rotor dynamics analysis of rotating machine systems. Mechatronics, 15, 1: 573-588.

ARTICLE INFORMATION

Received:

2012-05-31

Revised:

2012-09-24

Accepted:

2012-10-08

Available Online:

2013-03-01

Reddy, M.C.S., Sekhar, A.S. 2013. Application of artificial neural networks for identification of unbalance and looseness in rotor bearing systems. International Journal of Applied Science and Engineering, 11, 69–84. https://doi.org/10.6703/IJASE.2013.11(1).69

Cite this article: