REFERENCES

- Abdullah, A., Saraswat, S., Talib, F., 2023. Barriers and strategies for sustainable manufacturing implementation in SMEs: A hybrid fuzzy AHP-TOPSIS framework. Sustainable Manufacturing and Service Economics, 2, 100012.

- Ali, J., Bashir, Z., Rashid, T., 2021. WASPAS-based decision-making methodology with unknown weight information under uncertain evaluations. Expert Systems with Applications, 168, 114143.

- Alıemeke, B.N.G., Oladeinde, M., 2020. Box-Behnken design optimization of sand-casting process parameters. International Journal of Engineering Technologies IJET, 6(2), 25–36.

- Alizadeh, R., Soltanisehat, L., Lund, P.D., Zamanisabzi, H., 2020. Improving renewable energy policy planning and decision-making through a hybrid MCDM method. Energy Policy, 137, 111174.

- Altın, H., 2020. A comparison of the city life quality index for European cities using the Waspas and Vikor methods. Journal of Business Economics and Finance, 9(2), 97–117.

- Arshad, A., Ali, H.M., Habib, A., Bashir, M.A., Jabbal, M. and Yan, Y., 2019. Energy and exergy analysis of fuel cells: A review. Thermal Science and Engineering Progress, 9, 308–321.

- Bagal, D.K., Giri, A., Pattanaik, A.K., Jeet, S., Barua, A., Panda, S.N., 2021. MCDM optimization of characteristics in resistance spot welding for dissimilar materials utilizing advanced hybrid Taguchi method-coupled CoCoSo, EDAS and WASPAS method. In Next Generation Materials and Processing Technologies: Select Proceedings of RDMPMC 2020, 475–490.

- Bagal, D.K., Mahapatra, S.K., Barua, A., Jeet, S., Pattanaik, A.K., Patnaik, D., 2021. Multi-parametric optimization of wire-EDM of Inconel 718 super alloy using Taguchi-coupled WASPAS method. In Advances in Mechanical Processing and Design: Select Proceedings of ICAMPD 2019, 459–467.

- Behera, N.C., Jeet, S., Nayak, C.K., Bagal, D.K., Panda, S.N., Barua, A., 2022. Parametric appraisal of strength and hardness of resin compacted sand castings using hybrid Taguchi-WASPAS-Material Generation Algorithm. Materials Today: Proceedings, 50, 1226–1233.

- Çelikbilek, Y., Tüysüz, F., 2020. An in-depth review of theory of the TOPSIS method: An experimental analysis. Journal of Management Analytics, 7(2), 281–300.

- Chadaga, K., Prabhu, S., Vivekananda, B.K., Niranjana, S., Umakanth, S., 2021. Battling COVID-19 using machine learning: A review. Cogent Engineering, 8(1), 1958666.

- Chicco, D., Warrens, M.J., Jurman, G., 2021. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. Peerj computer science, 7, e623.

- Chodha, V., Dubey, R., Kumar, R., Singh, S., Kaur, S., 2022. Selection of industrial arc welding robot with TOPSIS and Entropy MCDM techniques. Materials Today: Proceedings, 50, 709–715.

- Chowdhury, P., Paul, S.K., 2020. Applications of MCDM methods in research on corporate sustainability: A systematic literature review. Management of Environmental Quality: An International Journal, 31(2), 385–405.

- Deng, W., Shang, S., Cai, X., Zhao, H., Song, Y., Xu, J., 2021. An improved differential evolution algorithm and its application in optimization problem. Soft Computing, 25, 5277–5298.

- Dietmair, A., Verl, A., 2009. A generic energy consumption model for decision making and energy efficiency optimization in manufacturing. International Journal of Sustainable Engineering, 2(2), 123–133.

- Dincera, I., Hussain, M.M. and Al-Zaharnah, I., 2004. Energy and exergy use in the utility sector of Saudi Arabia. Desalination, 169(3), 245–255.

- Dutta, S., Sarma, D.K., 2024. Multi-response optimization of machining parameters to minimize the overcut and circularity error during micro-EDM of nickel-titanium shape memory alloy. Advances in Materials and Processing Technologies, 10(1), 1–21.

- Emovon, I., Oghenenyerovwho, O.S., 2020. Application of MCDM method in material selection for optimal design: A review. Results in Materials, 7, 100115.

- Ghaleb, A.M., Kaid, H., Alsamhan, A., Mian, S.H., Hidri, L., 2020. Assessment and comparison of various MCDM approaches in the selection of manufacturing process. Advances in Materials Science and Engineering, 2020(1), 4039253.

- Goswami, S.S., Behera, D.K., Afzal, A., Razak Kaladgi, A., Khan, S.A., Rajendran, P., Subbiah, R., Asif, M., 2021. Analysis of a robot selection problem using two newly developed hybrid MCDM models of TOPSIS-ARAS and COPRAS-ARAS. Symmetry, 13(8), 1331.

- Hajduk, S., 2021. Multi-criteria analysis in the decision-making approach for the linear ordering of urban transport based on TOPSIS technique. Energies, 15(1), 274.

- Hocine, A., Zhuang, Z.Y., Kouaissah, N., Li, D.C., 2020. Weighted-additive fuzzy multi-choice goal programming (WA-FMCGP) for supporting renewable energy site selection decisions. European Journal of Operational Research, 285(2), 642–654.

- Hua, Y., Liu, Q., Hao, K., Jin, Y., 2021. A survey of evolutionary algorithms for multi-objective optimization problems with irregular Pareto fronts. IEEE/CAA Journal of Automatica Sinica, 8(2), 303–318.

- Hutagalung, J., Boy, A.F., Yahdie, M.A., 2022. Implementasi Metode Weighted Aggregated Sum Product Assesment (WASPAS) dalam Pemilihan Oli Mesin Sepeda Motor 150 CC. Bulletin of Informatics and Data Science, 1(2), 55–63.

- Jauhari, W.A., Mayangsari, S., Kurdhi, N.A., Wong, K.Y., 2017. A fuzzy periodic review integrated inventory model involving stochastic demand, imperfect production process and inspection errors. Cogent Engineering, 4(1), 1308653.

- Jeong, D., 2022. A study on evaluation of online trading system in MRO supply business. The Journal of Economics, Marketing and Management, 10(2), 1–13.

- Jeong, I.J., Lee, D.H., Son, Y.J., 2024. A process capability function approach to multiple response surface optimization based on a posterior procedure. Quality Engineering, 1–14.

- Koohathongsumrit, N., Chankham, W., 2022. A hybrid approach of fuzzy risk assessment-based incenter of centroid and MCDM methods for multimodal transportation route selection. Cogent Engineering, 9(1), 2091672.

- Kouaissah, N., Hocine, A., 2020. Optimizing sustainable and renewable energy portfolios using a fuzzy interval goal programming approach. Computers and Industrial Engineering, 144, 106448.

- Kundu, J., Singh, H., 2016. Friction stirs welding: multi-response optimization using Taguchi-based GRA. Production and Manufacturing Research, 4(1), 228–241.

- Kunovjanek, M., Wankmüller, C., 2021. An analysis of the global additive manufacturing response to the COVID-19 pandemic. Journal of Manufacturing Technology Management, 32(9), 75–100.

- Li, Z., Lu, D., Gao, X., 2021. Optimization of mixture proportions by statistical experimental design using response surface method-A review. Journal of Building Engineering, 36, 102101.

- Liaw, C.F., Hsu, W.C.J., Lo, H.W., 2020. A hybrid MCDM model to evaluate and classify outsourcing providers in manufacturing. Symmetry, 12(12), 1962.

- Majumder, A., Das, P.K., Majumder, A., Debnath, M., 2014. An approach to optimize the EDM process parameters using desirability-based multi-objective PSO. Production and Manufacturing Research, 2(1), 228–240.

- Miç, P., Antmen, Z.F., 2021. A decision-making model based on TOPSIS, WASPAS, and MULTIMOORA methods for university location selection problem. Sage Open, 11(3), 21582440211040115.

- Mousavi, S., Thiede, S., Li, W., Kara, S., Herrmann, C., 2016. An integrated approach for improving energy efficiency of manufacturing process chains. International Journal of Sustainable Engineering, 9(1), 11–24.

- O’Mahony, D., McDermott, O., Lynch, A., Cormican, K., 2023. The impact of serialisation on operational efficiency and productivity in pharmaceutical sites: A literature review. Cogent Engineering, 10(1), 2231729.

- Odunfa, M., Joel, O.L., 2022. Energy, exergy and cost analysis of flour production from wheat in Nigeria: Case study of Nigeria Eagle Flour mills, Ibadan. Global Journal of Engineering and Technology Advances, 13(01), 067–097.

- Panda, S.N., Pattanaik, A.K., Patel, A.K., Nayak, S., Patra, P., Bagal, D.K., 2023. Process parameter optimization for machining of Ti-6Al-4V using WASPAS and multi-objective genetic algorithm along with exponential trend line analysis. Materials Today: Proceedings.

- Pawaree, N., Phokha, S., Phukapak, C., 2024. Multi-Response Optimization of charcoal briquettes process for green economy using a novel TOPSIS linear programming and Genetic Algorithms based on Response Surface Methodology. Results in Engineering, 102226.

- Rajesh, R., 2021. Optimal trade-offs in decision-making for sustainability and resilience in manufacturing supply chains. Journal of Cleaner Production, 313, 127596.

- Rokooei, S., Alvanchi, A., Rahimi, M., 2022. Perception of COVID-19 impacts on the construction industry over time. Cogent Engineering, 9(1), 2044575.

- Saeed, M.A., Junejo, F., Amin, I., 2024. Optimizing sustainable machining for magnesium alloys: A comparative study of GRA and TOPSIS. Cogent Engineering, 11(1), 2308986.

- Sahoo, S.K., Goswami, S.S., 2023. A comprehensive review of multiple criteria decision-making (MCDM) methods: advancements, applications, and future directions. Decision Making Advances, 1(1), 25–48.

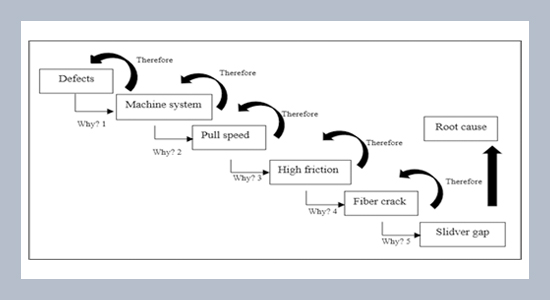

- Sakdiyah, S.H., Eltivia, N., Afandi, A., 2022. Root cause analysis using fishbone diagram: company management decision making. Journal of Applied Business, Taxation and Economics Research, 1(6), 566–576.

- Sałabun, W., Wątróbski, J., Shekhovtsov, A., 2020. Are mcda methods benchmarkable? A comparative study of topsis, vikor, copras, and promethee ii methods. Symmetry, 12(9), 1549.

- Sapkota, G., Das, S., Sharma, A., Ghadai, R. K. 2023. Comparative study of WASPAS, EDAS and MOORA MCDM techniques in selection of coconut shell ash reinforced aluminum metal matrix composite. In AIP Conference Proceedings, 2786(1).

- Shabbir, M.S., Wisdom, O., 2020. The relationship between corporate social responsibility, environmental investments and financial performance: evidence from manufacturing companies. Environmental Science and Pollution Research, 27(32), 39946–39957.

- Sharma, A.K., Mukherjee, I., 2020. Enhanced multi-objective solution approach for multiple quality characteristics optimization problems considering predictive uncertainties. International Journal of Quality and Reliability Management, 37(1), 112–144.

- Singh, M., Singh, K. and Sethi, A.S., 2020. Analytical hierarchy process and TOPSIS for selecting best parameters of green manufacturing. Measuring Business Excellence, 24(3), 345–365.

- Singh, S., Agrawal, V., SAXENA, K. K., Mohammed, K. A. 2023. Optimization on manufacturing processes at Indian industries using TOPSIS. Indian Journal of Engineering and Materials Sciences (IJEMS), 30(1), 32–44.

- Sotoudeh-Anvari, A., 2022. The applications of MCDM methods in COVID-19 pandemic: A state of the art review. Applied Soft Computing, 126, 109238.

- Sreeraj, P., Kumaran, S.T., Kumar, S.S., Uthayakumar, M., Pethuraj, M., 2022. Application of MCDM based hybrid optimization of WEDM process parameters. Materials Today: Proceedings, 50, 1186–1192.

- Sriburum, A., Wichapa, N., Khanthirat, W., 2023. A novel TOPSIS linear programming model based on the Taguchi Method for solving the Multi-Response Optimization Problems: A case study of a fish scale scraping machine. Engineered Science, 23, 882.

- Stefanini, R., Barbara, B., Vignali, G., 2022. Manufacturing, use phase or final disposal: where to focus the efforts to reduce the environmental impact of a food machine? Production and Manufacturing Research, 10(1), 624–640.

- Stević, Ž., Pamučar, D., Puška, A., Chatterjee, P., 2020. Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to Compromise solution (MARCOS). Computers and industrial engineering, 140, 106231.

- Sweeting, W.J., Hutchinson, A.R., Savage, S.D., 2011. Factors affecting electric vehicle energy consumption. International Journal of Sustainable Engineering, 4(3), 192–201.

- To-On, P., Wichapa, N., Khanthirat, W., 2023. A novel TOPSIS linear programming model based on response surface methodology for determining optimal mixture proportions of lightweight concrete blocks containing sugarcane bagasse ash. Heliyon, 9(7).

- Vazquez Hernandez, J., Elizondo Rojas, M.D., 2023. Improving spare parts (MRO) inventory management policies after COVID-19 pandemic: A Lean Six Sigma 4.0 project. The TQM Journal, 36(6), 1627–1650.

- Waheed, M.A., Jekayinfa, S.O., Ojediran, J.O., Imeokparia, O.E., 2008. Energetic analysis of fruit juice processing operations in Nigeria. Energy, 33(1), 35–45.

- Wicaksono, F.D., Ciptomulyono, U., Artana, K.B., Irawan, M.I., 2022. Evaluation of the fatal accident factors in the petroleum industry using hybrid Gaussian multi-criteria decision-making (MCDM) approach. Cogent Engineering, 9(1), 2154003.

- Yu, Z., Guindani, M., Grieco, S.F., Chen, L., Holmes, T.C., Xu, X., 2022. Beyond t test and ANOVA: applications of mixed-effects models for more rigorous statistical analysis in neuroscience research. Neuron, 110(1), 21–35.

- Yusuf, L.A., Popoola, K., Musa, H., 2021. A review of energy consumption and minimization strategies of machine tools in manufacturing process. International Journal of Sustainable Engineering, 14(6), 1826–1842.

- Zhang, Q., Yi, H., Yu, Z., Gao, J., Wang, X., Lin, H. and Shen, B., 2018. Energy-exergy analysis and energy efficiency improvement of coal-fired industrial boilers based on thermal test data. Applied Thermal Engineering, 144, 614–627.

- Zhao, X., Deng, Q., Liu, X., Zhang, L., Wu, S., Jiang, C., 2022. Integrated scheduling of distributed service resources for complex equipment considering multiple on-site MRO tasks. International Journal of Production Research, 60(10), 3219–3236.

- Zhou, C., Qi, L., Liu, X., Bo, H., 2022. MRO configuration management for complex products. Journal of Systems Science and Systems Engineering, 31(3), 359–380.