Khairedin M. Abdallaa and Wai-Fah Chenb* a Department of Civil Engineering, Jordan University of Science and Technology, 22110, Irbid, Jordan

b Department of Civil and Environmental Engineering, University of Hawaii at Manoa, Honolulu, Hawaii, HI 96822, U.S.A.

Download Citation:

|

Download PDF

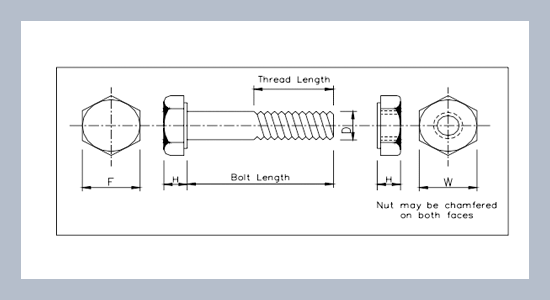

This paper presents results of a series of tests performed using ¾ in. diameter A325 and A490 bolts. The resulting relationship between torque – tension for the bolt – nut – washer assembly is used to explain its behavior as the length and location of treatment surface are varied. Tests were performed upon one hundred sixty four bolts; eighty A325 of three inches in length, fifty-two A325 of six inches in length, twenty A490 of three inches in length, and twelve A490 of six inches in length. One hundred sixty four nuts and washers were tested, one hundred nuts type 2H, and fifty six nuts type C and eight nuts type D to determine the effect of the variables (nut type, bolt length, bolt type and Control Fluid) on the torque-tension relationship of the bolt-nut-washer assembly. Hundreds of experiments using replicate samples for statistical reliability were conducted to establish the effect of the variables on the tension-torque relationship of the bolt-nut-washer assemblage. The principal relationship in turn-of-nut installation is that between elongation and bolt pretension, the tension -torque relationship is the factor that reflects the bolt pretension in an installation to be expected in a properly tightened connection. Control Fluid was found to decrease the coefficient of friction on coated parts and to control the tension obtained with a given torque upon assembly.ABSTRACT

Keywords:

bolt pretension; high strength bolts; bolt treatment; bolt pre load; bolt lubricant.

Share this article with your colleagues

[1] Research council on structural connections, 2000. “Specification for Structural Joints Using ASTM A325 or A490 bolts”. by RCSC.REFERENCES

[2] Bell, M. H. High strength steel bolts in structural practice. Transactions of American Society of Civil Engineering, 122: 1-21.

[3] Bindigo, R. A. and Rumpf, J. L. “Calibration and Installation of High Strength Bolts”. Fritz Laboratory Report No. 271.7, Leigh University.

[4] Rumpf, J. L. and Fisher, J. W.Calibration of A325 bolts. Journal ofStructural Engineering, 89, 6: 215-234.

[5] Sterling, G. H., Troup, E. W. J., and Fisher, J. W. Calibration of A490 High-strength bolts. Journal of Structural Engineering, 91, 5: 279-298.

[6] S. Department of Transportation Federal Highway Administration. 1991. “High-strength Bolts for Bridges”. Report No. FHWA-SA-91031.

[7] Ham, H. and Ryan, D. G.. 1932. “An Experimental Investigation of Screw Thread, Bulletin 247”. Engineering experiment station, University of Illinois, Urbana.

[8] Spotts, M. F. “Design of Machine Elements”. 4th Edition, Prentice-Hall, Inc., Englewood Cliffs, New Jersey.

[9] Lambert, T. H. Effect of variation in the screw thread coefficient of friction on the clamping force of bolted connections. Journal of Mechanical Engineering Science, 4, 4: 401-403.

[10] Faella, Ciro, Piluso, Vincenzo, and Rizzano, Gianvittorio. Experimental analysis of bolted connections: Snug versus preloaded bolts. Journal of Structural Engineering: 765-774.

ARTICLE INFORMATION

Accepted:

2004-01-20

Available Online:

2004-03-02

Abdalla, K.-M., Chen, W.-F., 2004. Effect of control fluid on surface treatments of high strength bolts, International Journal of Applied Science and Engineering, 2, 1–15. https://doi.org/10.6703/IJASE.2004.2.(1).1

Cite this article: