Satya Sai Srikanta*, P. S. Mukherjeeb, and R. Bhima Raoc aAssistant Professor, Department of Electronics and Communication, SRM University,Modinagar ,Ghaziabad, India

bChief Scientist, Advance Material Technology, IMMT (CSIR Group) Bhubaneswar,Odisha, India

cChief Scientist, Mineral Processing Department, IMMT (CSIR Group) Bhubaneswar,Odisha, India

Download Citation:

|

Download PDF

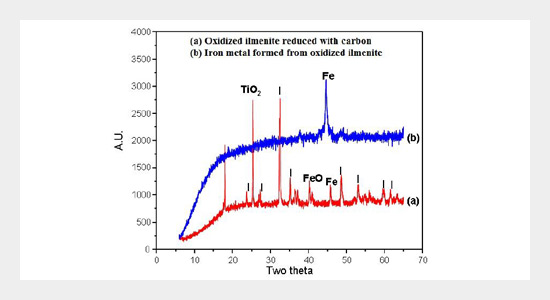

Microwave energy has potential for the efficient heating of minerals. Minerals or materials, which couple to microwave energy are called dielectrics and many valuable minerals are found to be dielectric. The mineral ilmenite is one which shows good dielectric heating characteristics. In this paper the effect of microwave heat energy on the partial reduction of oxidized ilmenite oxidized in a conventional muffle furnace at 1000°C for 3 hour is also attempted. Carbon as low ash coke with 87.5% purity act as an additive was used for reduction of ilmenite at different time intervals using microwave sintering furnace. The results of these investigations indicate that at one minute of time the metallic iron formed contain 0.39% and of course no observation in mineral phases was noticed. At three minutes of duration of time, a partial phase transformation of ilmenite was observed and the metallic iron contain is 1.65%. Interestingly at above ten minutes duration of time a distinct metallic iron phase containing 35% metallic iron is seen in microwave furnace. Further studies are in progress.ABSTRACT

Keywords:

Microwave heating; electromagnetic; reductant; susceptor; ilmenite.

Share this article with your colleagues

[1] Chen, T. T., Dutrizac, J. E., Haque K. E., Wyslouzil, W., and Kashyap, S. 1984. The Relative Transparency of Minerals to Microwave Radiation. Canadian metallurgical quarterly, 23, 1: 349-351.REFERENCES

[2] Bhima Rao, R. and Patnaik, N. 2004. Microwave Energy in Mineral Processing-a Review. IE(I) Mineral Journal,84, 1: 56-61.

[3] Pickles, C. A. 2009. Microwaves in extractive metallurgy: Part 1-A Review of Fundamental. Elsevier Journa: doi:10.1016/j.mineng.2009.02.015, 1: 1102-1111.

[4] Pickles, C. A. 2009. Microwaves in extractive metallurgy: Part 1-A Review of Applications. Elsevier Journal: doi:10.1016/j.mineng.2009.02.014, 1: 1112-1118.

[5] Kelly, R. M. and Rawson, N. A. 1998. Microwave Reduction of oxidised ilmenite concentrates. Minerals engineering Jr, 11, 1: 1427-1438.

[6] Omer, Y. 2004. The effect of heat treatment on colemanite processing: a ceramics application. Powder Technology Jr, 142, 1: 7 -12.

[7] Haque, K. E.1999. Microwave energy for mineral treatment processes-a brief review. International Journal of Mineral Processing, 57, 1: 1-24.

[8] Xia, D. K. and Pickles, C. A. 1997. Applications of microwave energy in extractive metallurgy-a review, CIM Bull. 90,1: 96-107.

ARTICLE INFORMATION

Received:

2012-06-22

Revised:

2012-12-23

Accepted:

2013-02-19

Available Online:

2013-09-01

Srikant, S.S., Mukherjee, P.S., Rao, R.B. 2013. Effect of heat treatment in microwave furnace for placer ilmenite. International Journal of Applied Science and Engineering, 11, 245–250. https://doi.org/10.6703/IJASE.2013.11(3).245

Cite this article: