Mahmoud Samir EL-Wazery* and Ahmed Reffat EI-Desouky Department of Production Engineering and Mechanical Design, Faculty of Engineering, Menoufiya University, Shebin El-Kom, Egypt

Download Citation:

|

Download PDF

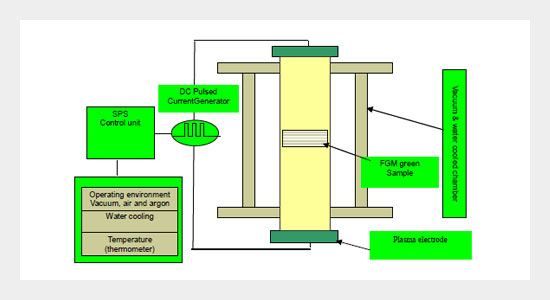

Functionally graded materials (FGM) in the form of layered structure consisting of yttria stabilized zirconia (YSZ) and nickel were fabricated by spark plasma sintering procedure. The relative density, linear shrinkage and Vickers hardness of each layer of graded materials were measured. The microstructure and the composition of these components were studied. The results obtained show that functionally graded materials produced by spark plasma sintering exhibited a low porosity level and consequently fully dense specimens. Also, the results demonstrate that the composition and microstructure of YSZ/Ni FGM have the expected gradient distribution. There are no macroscopic distinct interfaces in YSZ/Ni FGM due to the gradient change in components. This good continuity of microstructure can eliminate the disadvantage of traditional macroscopic interface in YSZ/Ni joint, and reflect the design idea of FGM. Vicker’s hardness of YSZ/Ni is lower than that of pure zirconia (YSZ) and increases by increasing the relative density of the layer of YSZ/Ni.ABSTRACT

Keywords:

Functionally graded materials (FGM); yttria stabilized zirconia (YSZ); spark plasma sintering (SPS); relative density and Microstructure.

Share this article with your colleagues

[1] Yamanouchi, M., Hirai, T., and Shiota, I. 1990. Proceedings of the First International Symposium on Functionally Gradient Materials. FGM Forum, Tokyo, Japan.REFERENCES

[2] Neubrand, A. and Rodel, J. 1997. Gradient materials: an overview of a novel concept, Z Metallkd, 88 , 358–371.

[3] Kieback, B., Neubrand, A., and Riedel, H. 2003. Processing technique for functionally graded material. Material Science Engineering and Structure, 362: 81-105.

[4] Miyamoto, Y., Kaysser, A., Rabin, B., and Kawasaki, A. 1999.“Functionally graded materials: design processing and applications”. Kluwer, Dordrecht, the Netherlands, Ford RG.

[5] Wosko, M. and Prazmowska, J. 2006. AIII-BV(N) Photodetectors with functionally graded active area. Proceedings of the Symposium on Photonics Technologies for 7th Framework Program Wroclaw, 12-14.

[6] Kawasaki, A. and Watanabe, R. 2002. Thermal fracture behavior of metal/ceramic functionally graded materials. Engineering Fracture Mechanics, 69: 1713–1728.

[7] Ruys, J., Popov, B., Sun, D., Russell, J., and Murray, J. 2001. Functionally graded electrical/thermal ceramic systems. Journal of the European Ceramic Society, 21: 2025–2029.

[8] Matula, G., Jardiel, T., Jimene, R., Levenfeld, B., and Várez, A. 2008. Microstructure, mechanical and electrical properties of Ni-YSZ anode supported solid oxide fuel cells. International Journal of Materials Science and Engineering, 32: 21-25.

[9] Rajeswari, K., Buchi, M., Hareesh, U., Srinivasa, Y., Das, R., and Johnson, R. 2011. Studies on ionic conductivity of stabilized zirconia ceramics (8YSZ) densified through conventional and non-conventional sintering methodologies. Ceramics Internationa, l37: 3557–3564.

[10] Yu, J., Park, W., Lee, S., and Woo, K. 2008. Microstructural effects on the electrical and mechanical properties of Ni-YSZ cermets for SOFC anode. Power Sources, 163: 921- 926.

[11] Menga, F., Liua, C., Zhangb, F., Tiana, Z., and Huanga, W. 2012. Densification and mechanical properties of fine-grained Al2O3–ZrO2 composites consolidated by spark plasma sintering. Journal of Alloys and Compounds, 512: 63–67.

[12] Lee, S., Lemberg, A., Cho, G., Roh, Y., and Ritchie, O. 2010. Mechanical properties of Si3N4–Al2O3 FGM joints with 15 layers for high-temperature applications. Journal of the European Ceramic Society, 30: 1743–1749.

[13] Shahrjerdi, A., Mustapha, F., Bayat, M., Sapuan, S., and Majid, A. 2011. Fabrication of functionally graded hydroxyapatite-titanium by applying optimal sintering procedure and powder metallurgy. International Journal of the Physical Sciences, 6: 2258-2267

[14] Wu, Li., Jin, X., Sun, Y., and Guo, L. 2009. Microstructure and mechanical properties of ZrO2/NiCr functionally graded materials. Materials Science and Engineering A, 509: 63–68.

[15] Zhou, S. and Li, Q. 2008. Microstructural design of connective base cells for functionally graded materials. Materials Letters, 62: 4022–4024

[16] Lia, J., Zenga, X., Tanga, N., and Xiaob, P. 2003 Fabrication and thermal properties of a YSZ–NiCr joint with an interlayer of YSZ–NiCr functionally graded material. Journal of European Ceramic Society, 23: 1847–1853.

[17] Mishina, H., Inumaru, Y., and Kaitoku, K. 2008. Fabrication of ZrO2/AISI316L functionally graded materials for joint prostheses. Materials Science and Engineering A, 475: 141–147.

[18] EL-Wazery, S. M., EL-Desouky, R. A., Hamed, A. O., Mansour, A. N., and Hassan, A. A. 2012. Fabrication and mechanical properties of zirconia/nickel functionally graded materials. International Journal of Advanced Materials Research, 463-464, 463-47.

[19] EL-Desouky, A. R. and EL-Wazery, M. S., 2013. Mixed Mode Crack Propagation of Zirconia/ Nickel Functionally Graded Materials. International Journal of Engineering (IJE), 26: 885-894.

[20] Jingchuan, Z., Zhongda, Y., Zhonghong, L., and Jian, L. 1996. Microstructure and thermal relaxation of ZrO2/Ni functionally graded materials. Trans. Nonferrous Met. Soc. China, 6: 94-99.

ARTICLE INFORMATION

Received:

2014-01-17

Revised:

2014-09-19

Accepted:

2014-09-22

Available Online:

2014-12-01

EL-Wazery, M.S., EI-Desouky, A.R. 2014. Fabrication and characteristics of 8YSZ/Ni functionally graded materials by applying spark plasma sintering procedure. International Journal of Applied Science and Engineering, 12, 313–321. https://doi.org/10.6703/IJASE.2014.12(4).313

Cite this article: