V. Ramakoteswara Raoa*, N. Ramanaiahb, and M. M. M. Sarcarc aMechanical Engineering Department., R. V. R & J. C College of Engineering, Guntur, India

bMechanical Engineering Department., Andhra University College of Engineering, Visakhapatnam, India

cJNTUA, Ananthapuramu, India

Download Citation:

|

Download PDF

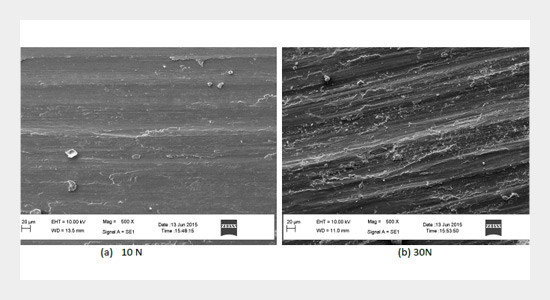

The AA7075 matrix reinforced with 2 to 10 weight % of TiC particles were made by stir casting. Effects of load on the wear and friction of the worn surfaces of matrix and composite pins sliding against a rotating disc have been investigated under dry condition. The wear tests were carried out using a pin-on-disc type apparatus at three different loads (10, 20 and 30N) under a constant velocity of 2m/s for a sliding distance of 2Km. The coefficient of friction was recorded and wear rate of the Aluminum metal matrix composite (AMMC) pins calculated from mass loss measurement. Scanning electron microscope (SEM) equipped with energy dispersive X-ray spectroscopy (EDX) was used to investigated the worn surface. It is observed that higher load leads to higher wear rate and lower coefficient of friction for matrix as well as composites. The hardness was found to increase with the increase in wt. % of the reinforcement.ABSTRACT

Keywords:

Titanium carbide; wear behavior; metal matrix composites; AA7075.

Share this article with your colleagues

[1] Cruz, S., Rey, P., Cabeza, M., Lieblich, M., and Merino, P. 2014. Effect of the TiC particle size on the extrusion of 7075 aluminium matrix composite. Presented at 16th European Conference on Composite Materials, June 22-26, 2014. Seville, Spain.REFERENCES

[2] Muruganandhan. P., Eswaramoorthi, M., and Kannakumar K. 2015. Aluminium fly ash composite – an experimental study with mechanical properties perspective. International Journal of Engineering Research, 3, 3: 78-83.

[3] Keshavamurthy. R., Ahmed, S. S., Laxman, A. M., Kumar, N. H. A., Shashidhara, M.N., and Reddy, Y. V. 2014. Tribological properties of Hot forged Al2024-TiB2 in-situ composite. Advanced Materials Manufacturing & Characterization, 4, 2:87-92.

[4] Starke Jr., E. A. and Staley, J. T. 1996. Application of modern aluminum alloys to aircraft. Progress in Aerospace Science, 32, 2-3: 131-172.

[5] Ipek, R. 2005. Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). Journal of Materials Processing Technology, 162-163: 71-75.

[6] Chawla, N., Andres, C., Jones, J. W., and Allison, J. E. 1999. The effect of reinforcement volume fraction and particle size on fatigue behavior of an aluminum alloy/sic composite. Industrial Heating, 66, 2: 61-66.

[7] Natarajan, N., Vijayarangan, S., and Rajendran, I. 2006. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear, 261, 7-8: 812-822.

[8] Shorowordi, K. M., Haseeb, A. S. M. A., and Celis, J. P. 2004. Velocity effects on the wear, friction and tribochemistry of aluminum MMC sliding against phenolic brake pad. Wear, 256, 11-12: 1176-1181.

[9] Ramesha, C. S., Anwar Khan, A. R., Ravikumar, N., and Savanprabhu, P. 2005. Prediction of wear coefficient of Al6061–TiO2 composites. Wear, 259, 1-6: 602-608.

[10] Kumar, S., Chakraborty, M., Sarma, V. S., and Murty, B. S. 2008. Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear, 265, 1-2: 134-142.

[11] Kennedy, A. R. and Wyatt, S. M. 2001. Characterising particle–matrix interfacial bonding in particulate Al–TiC MMCs produced by different methods. Composites Part A: Applied Science and Manufacturing, 32, 3-4: 555-559.

[12] Jerome, S., Ravisankar, B., Mahato, P. K., and Natarajan, S. 2010. Synthesis and evaluation of mechanical and high temperature tribological properties of in-situ Al–TiC composites. Tribology International. 43, 11: 2029-2036.

[13] Kaufman, J. G. 1999. “Properties of Aluminum Alloys: Tensile, Creep, and Fatigue Data at High and Low Temperatures”. ASM International. Washington. U.S.A.

[14] Kerti, I. 2005. Production of TiC reinforced aluminum composites with the addition of elemental carbon. Materials Letters, 59, 29-30: 3795–3800.

[15] Rao, V. R., Ramanaiah, N., and Sarcar, M. M. M. 2014. Fabrication and investigation on Properties of TiC reinforced Al7075 metal matrix composites. Applied Mechanics and Materials, 592-594: 349-353.

[16] Rao, V. R., Ramanaiah, N., and Sarcar, M. M. M. 2015. Dry Sliding Wear Behavior of Al7075 Reinforced with Titanium Carbide (TiC) Particulate Composites. In Proceedings of International Conference on Advances in Materials, Manufacturing and Applications (AMMA 2015), 39-44.

[17] Shi, D.-L., Feng, X.-Q., Huang, Y. Y., Hwang, K.-C., and Gao, H. 2004. The effect of nanotube waviness and agglomeration on the elastic property of carbon nanotube-reinforced composites. Journal of Engineering Materials and Technology, 126, 3: 250-257.

[18] Kumar, G. B. V., Rao, C. S. P., and Selvaraj, N. 2010. Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites—a review. Journal of Minerals & Materials Characterization & Engineering, 10, 1: 59-91.

[19] Akbulut, H., Durman, M, and Yilmaz, F. 2008. Dry wear and friction properties of δ-Al2O3 short fiber reinforced Al single bond Si (LM 13) alloy metal matrix composites. Wear, 215, 1-2: 170-179.

[20] Rohatgi, P. K., Tabandeh-Khorshid, M., Omrani, E., Lovell, M. R., and Menezes, P. L. 2013. Tribology of metal matrix composites. In Menezes, P. L., Nosonovsky, M., Ingole, S. P., Kailas, S. V., and Lovell, M. R. (Eds), Tribology for Science and Engineering (Chaptter 8, 233-268), SpringerLink.

[21] Kumar, G. B. V., Rao, C. S. P., and Selvaraj, N. 2012. Mechanical and dry sliding wear behavior of Al7075 alloy-reinforced with SiC particles. Journal of Composite Materials, 46, 10:1201-1209.

[22] Asif, M., Chandra, K., and Misra, P. S. 2011. Development of aluminium based hybrid metal matrix composites for heavy duty applications. Journal of Minerals & Materials Characterization & Engineering, 10, 14: 1337-1344.

[23] Mandal, A., Chakraborty, M., and Murty, B. S. 2007. Effect of TiB2 particles on sliding wear behaviour of Al–4Cu alloy. Wear, 262, 1-2: 160-166.

[24] Tyagi, R. 2005. Synthesis and tribologial characterization of in situ cast Al–TiC composites. Wear, 259, 1-6: 569-576.

[25] Cantwell, W. J. and Morton, J. 1991. The impact resistance of composite materials—a review. Composites, 22, 5: 347-362.

[26] Ramachandra, M. and Radhakrishna, K. 2007. Effect of reinforcement of flyash on sliding wear, slurry erosive wear and corrosive behavior of aluminium matrix composite. Wear, 262, 11-12: 1450-1462.

ARTICLE INFORMATION

Received:

2015-10-29

Revised:

2016-02-10

Accepted:

2016-02-11

Available Online:

2016-03-01

Rao, V.R., Ramanaiah, N., Sarcar, M.M.M. 2016. Dry sliding wear behavior of TiC –AA7075 metal matrix composites. International Journal of Applied Science and Engineering, 14, 27–37. https://doi.org/10.6703/IJASE.2016.14(1).27

Cite this article: